The solids addition process for chemical reactors can be a complicated and very dangerous process. Due to the presence of solvents, there is often a potentially explosive environment within vessel. The addition of dry solids introduces risk of static discharge and entrained oxygen which completes the highly dangerous fire trial and risk of a major deflagration event at the manway. Rheo offers many options for safe solids addition into your chemical reactor.

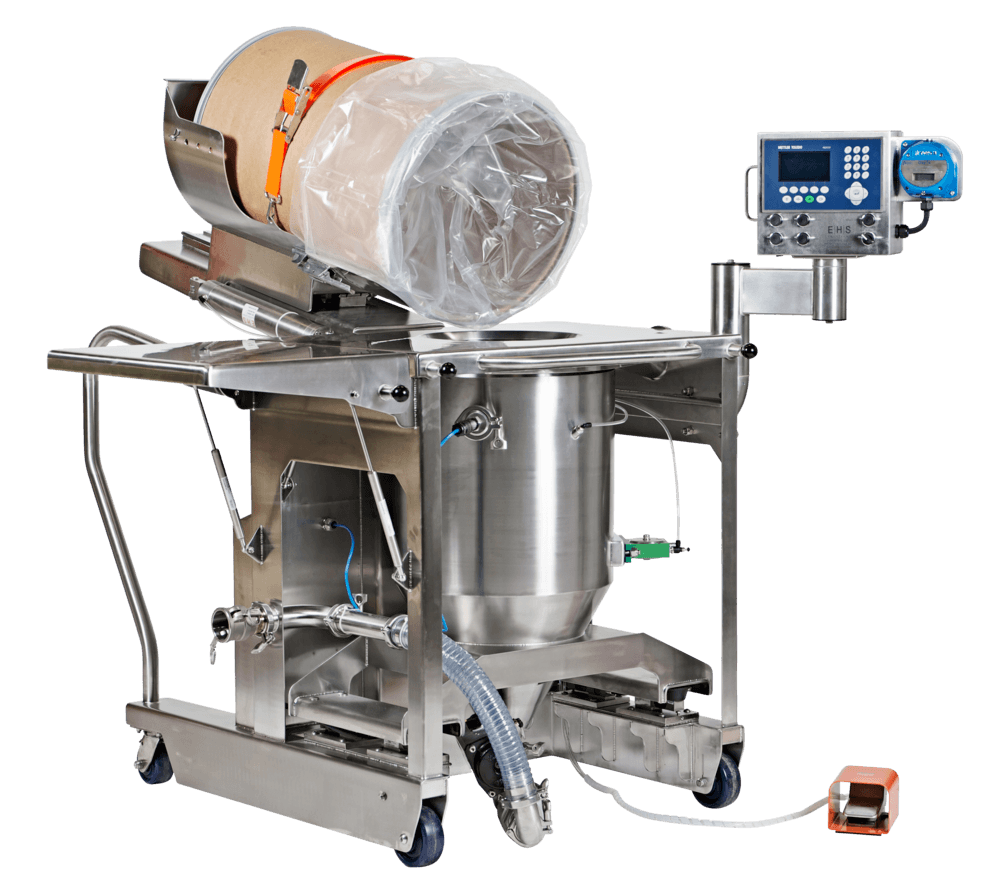

The Rheo Vacuum Transfer Stations an excellent tool for charging from both drums and bag-stock into a chemical reactor. This system utilizes the vessel vacuum system and does not require a separate vacuum powder pump. This portable system can be positioned up next to the reactor with a relatively short section of transfer hose. The short transfer hose, and utilization of the vessel vacuum source (not a pulsating powder pump) reduces the common challenges with vacuum receivers.

This package utilizes the Vacuum Transfer Station which has transformed the operator experience in the drum emptying process. Various containment configurations are available for this process.

We can also provide an active nitrogen inerting system to maintain less than 8% oxygen during the solids addition process.

If you are need to QS a portion of a drum or bag, we can provide an integrated weighing option.

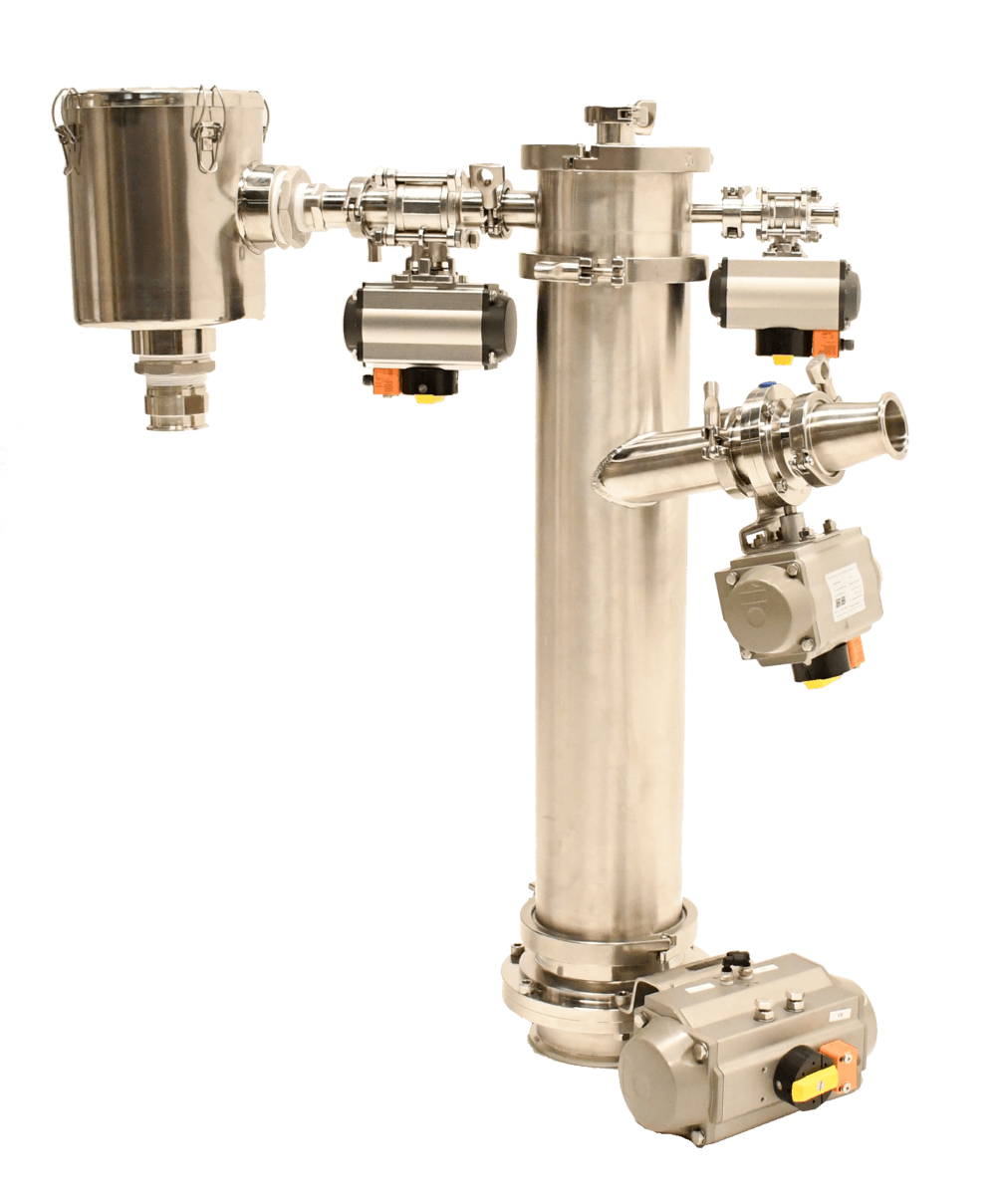

This application shows a subsurface addition process which may require a slightly more complex control system, but allows for improved dispersion of the powder within the vessel.

Vessel Charging

Vessel Charging Manway Additions

Manway Additions In-Floor Charge Chute

In-Floor Charge Chute Disperser Recirculation System

Disperser Recirculation System