The solids addition process for chemical reactors can be a complicated and very dangerous process. Due to the presence of solvents, there is often a potentially explosive environment within vessels. The addition of dry solids introduces the risk of static discharge and entrained oxygen which completes the highly dangerous fire triangle and could lead to a major deflagration event at the manway. Rheo offers many options for safe solids addition into your chemical reactor.

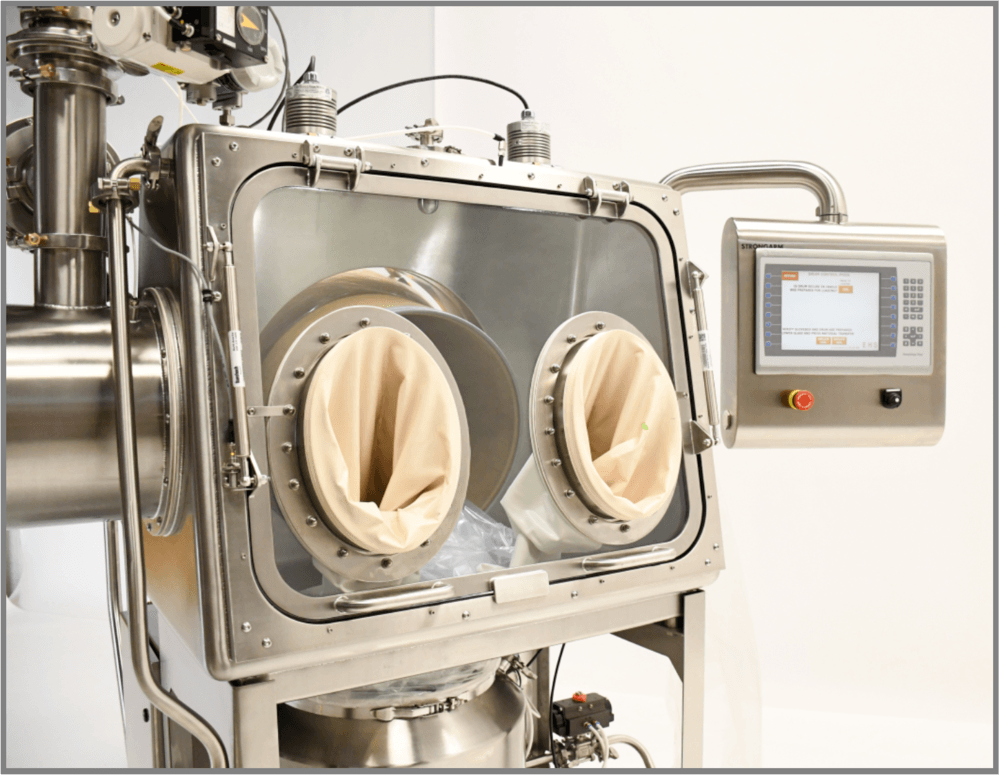

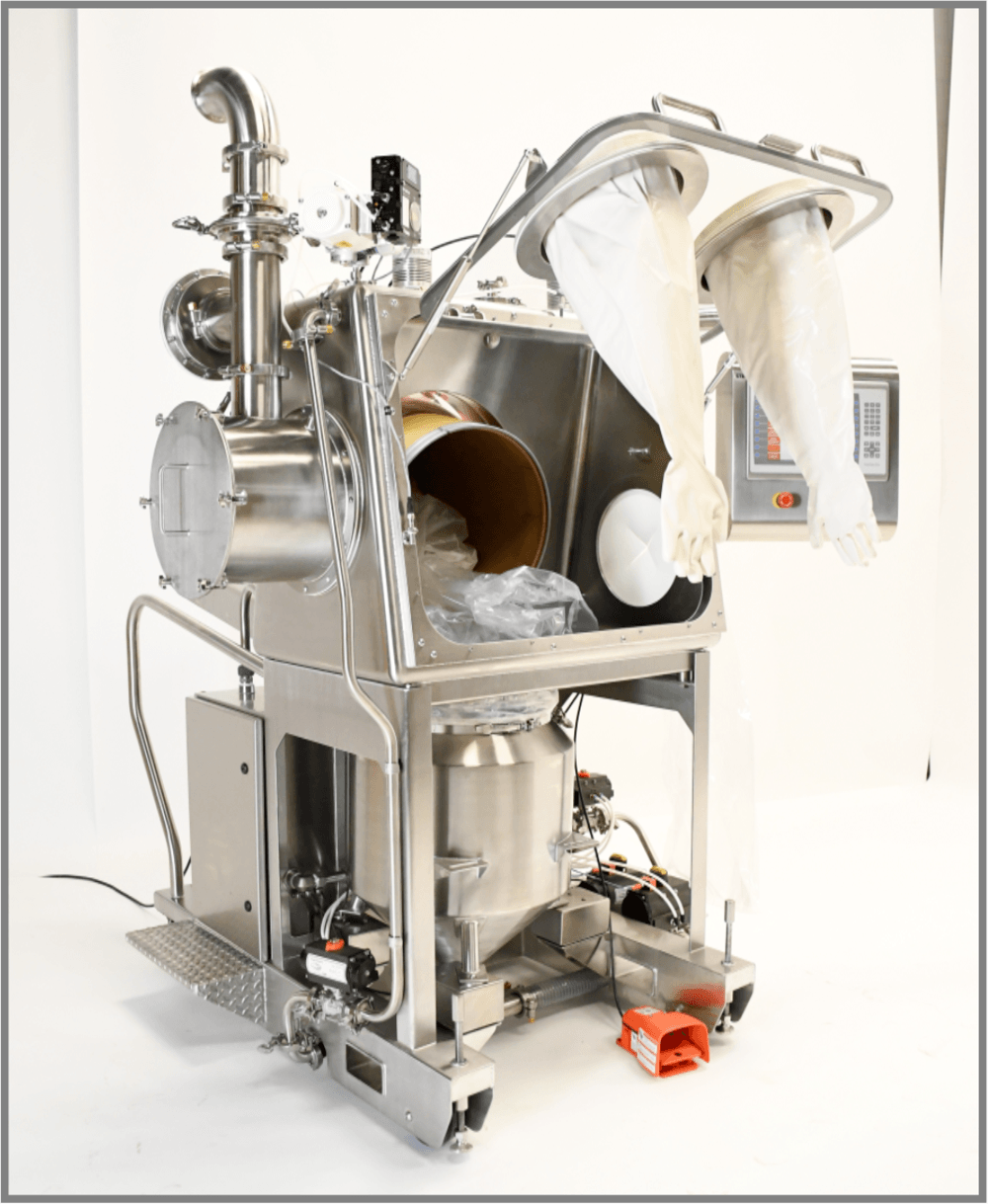

The Rheo Material Transfer Station [MTS], with the Vessel Charging package, is an easy to use workstation with integrated weighing and a sophisticated control package that allows for safe and efficient solids transfer into a process vessel.

This system allows for multiple drum transfers into a process tank while keeping operator exposure levels to less than 1 µg/m³ for the duration of the process. The MTS utilizes the central vacuum source on the vessel and does not require a separate powder transfer system.

Product is transferred through a small port on the vessel (manway remaining closed) to maintain an inert vessel and ensure operator safety. The PID control system reduces oxygen concentrations in the isolator below 1% for the powder transfer process while maintaining a high-containment isolator condition. Integrated load cells are used to weigh hopper contents while controls prevent material transfer if the weight in the hopper is over the target weight.

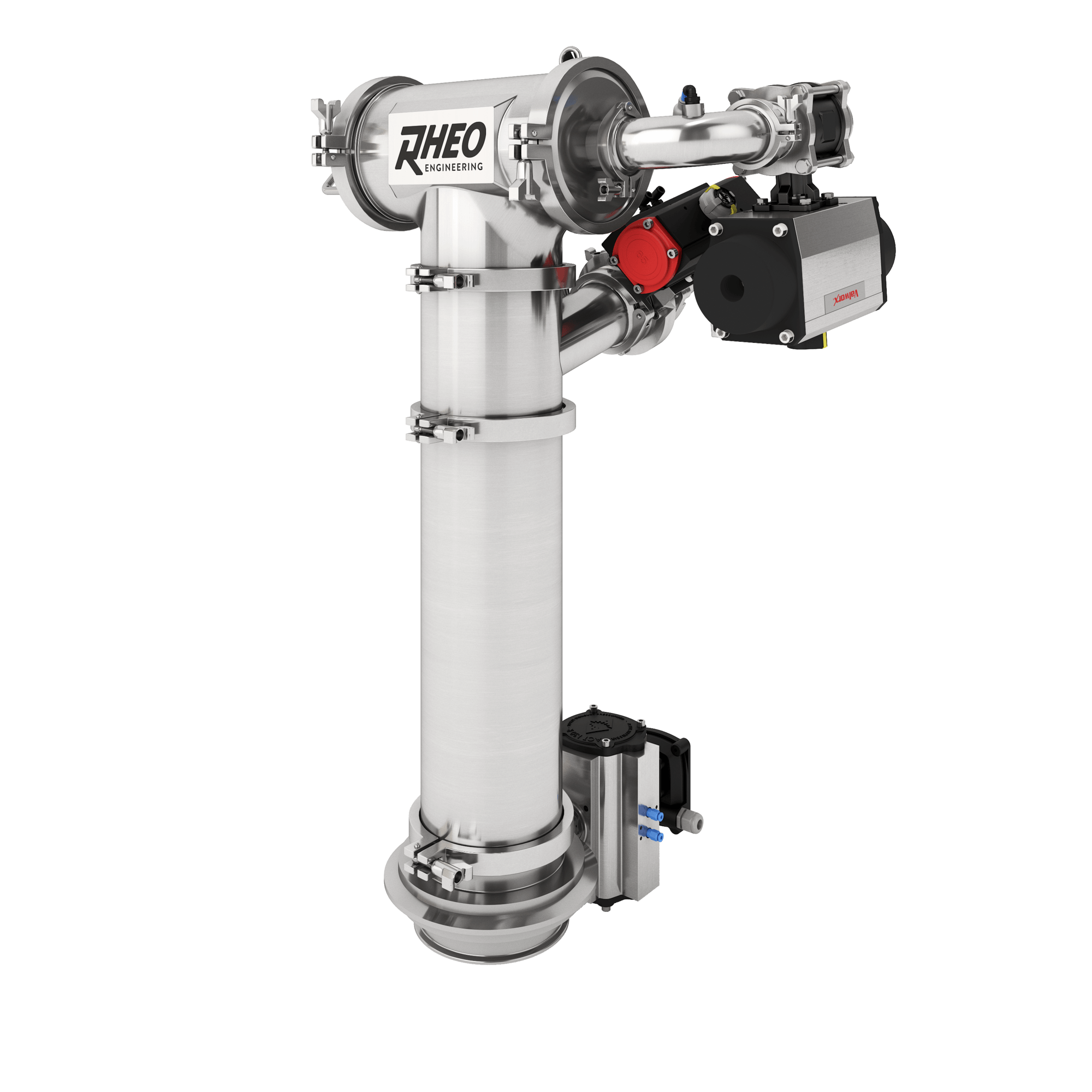

This system uses the Rheo proprietary AMPP (Actively Managed Plug Prevention) technology to optimize product conveyance throughput. CIP spray nozzles are used to clean the interior of the isolator and vacuum hopper.

Rheo hosted a webinar on Vessel Charging solutions. See additional information and request materials here.

Disperser Recirculation System

Disperser Recirculation System Manway Additions

Manway Additions In-Floor Charge Chute

In-Floor Charge Chute Subsurface Vacuum Additions

Subsurface Vacuum Additions