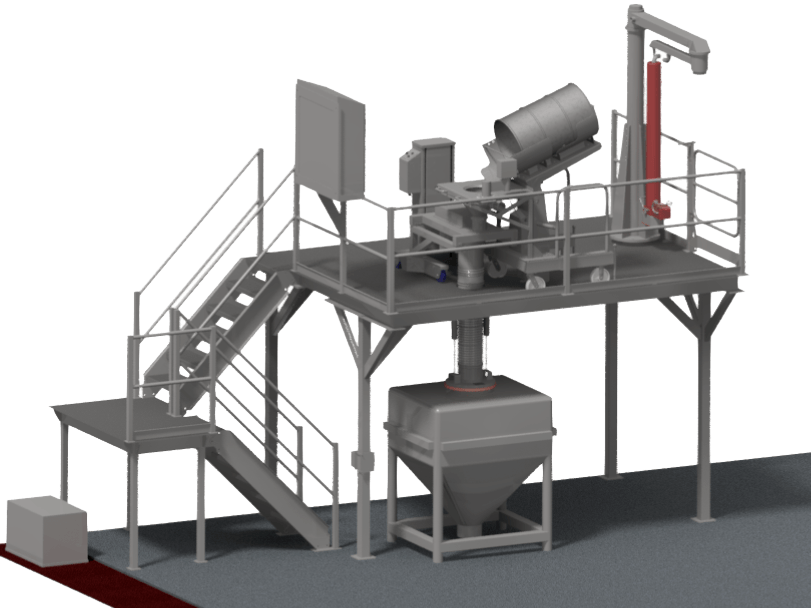

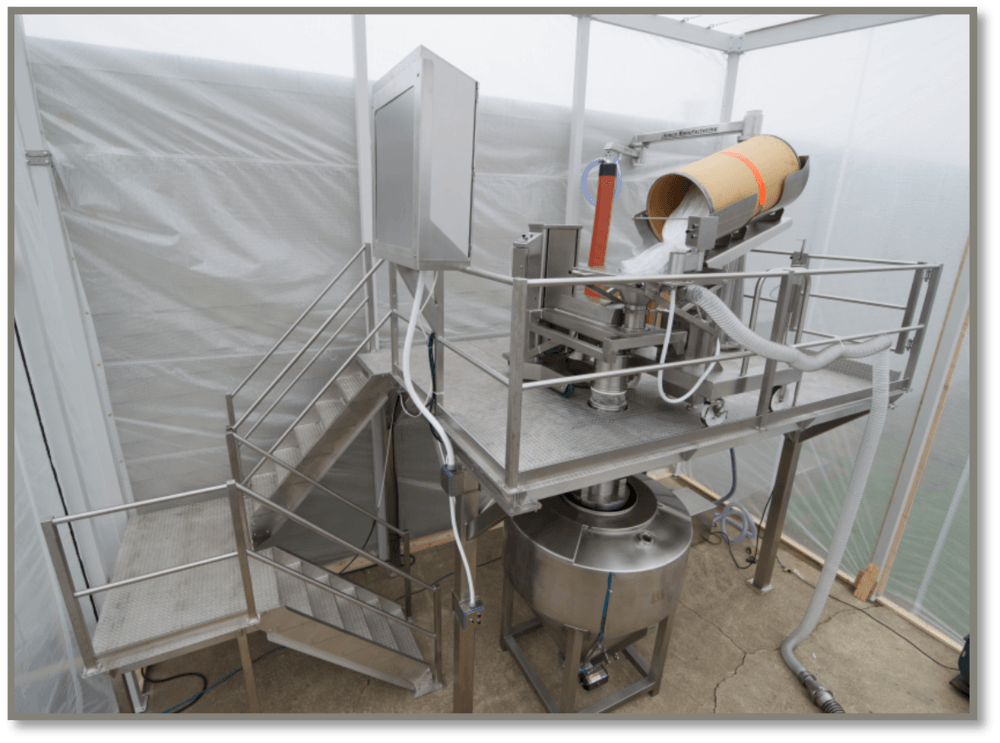

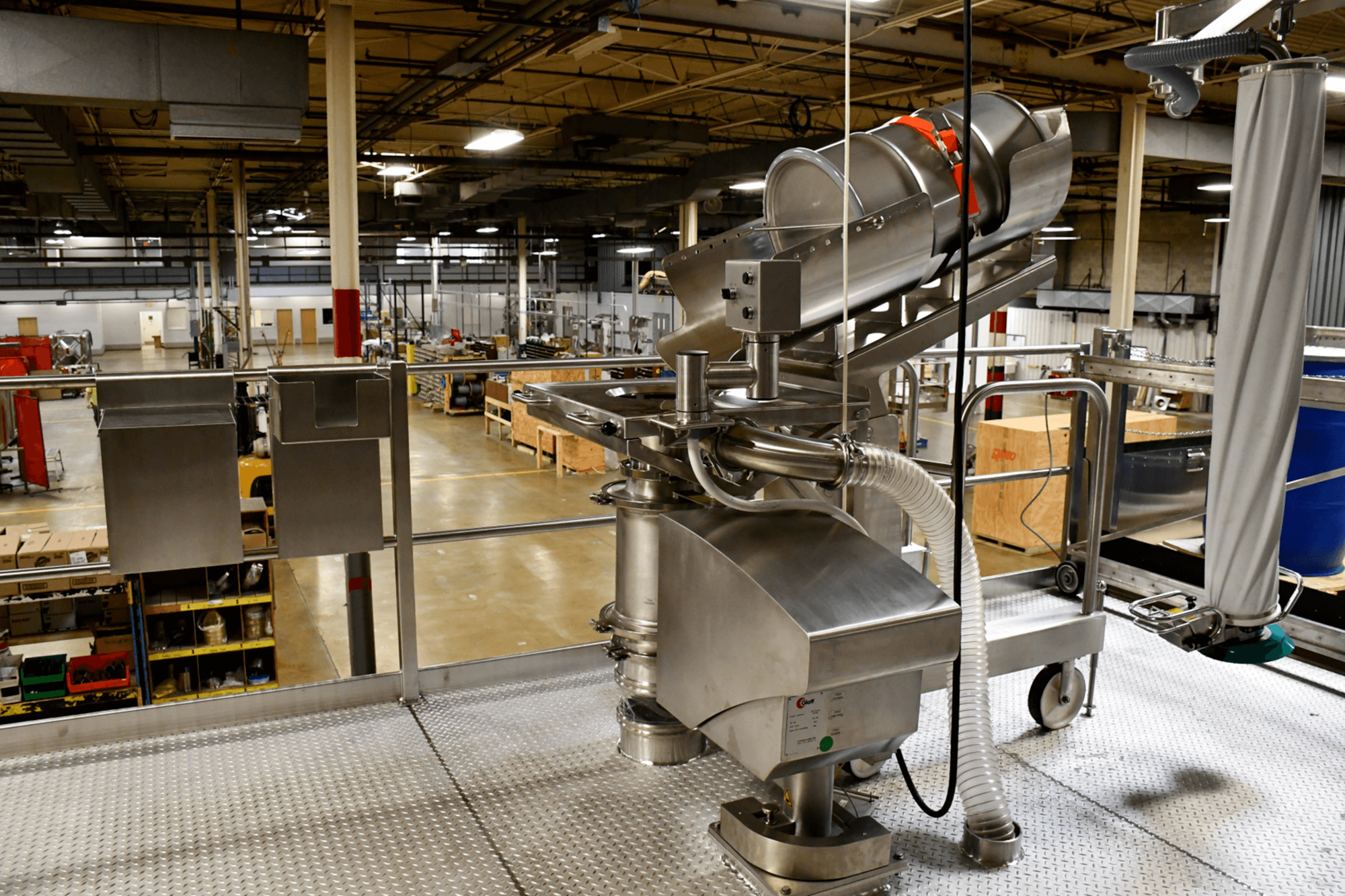

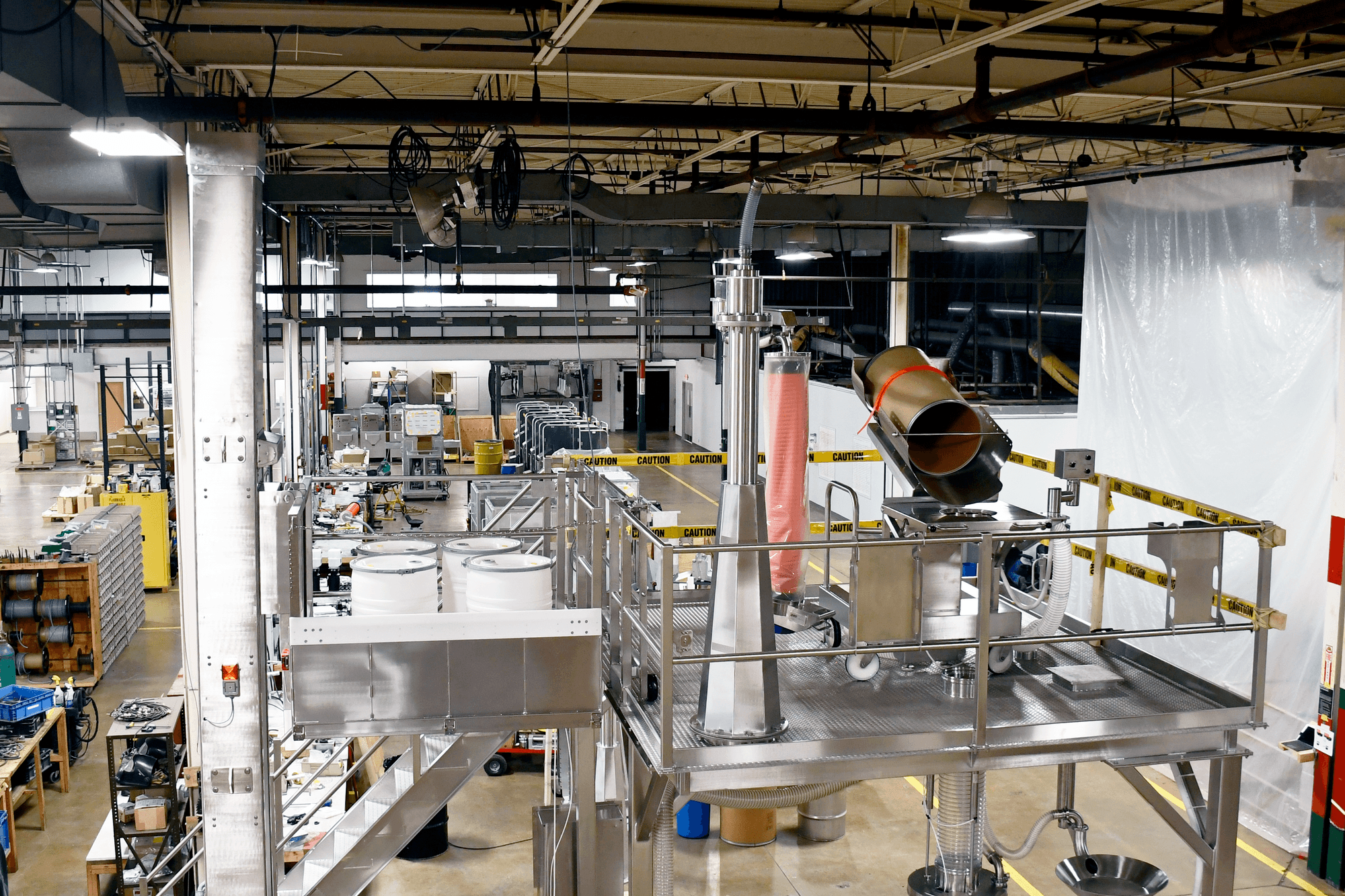

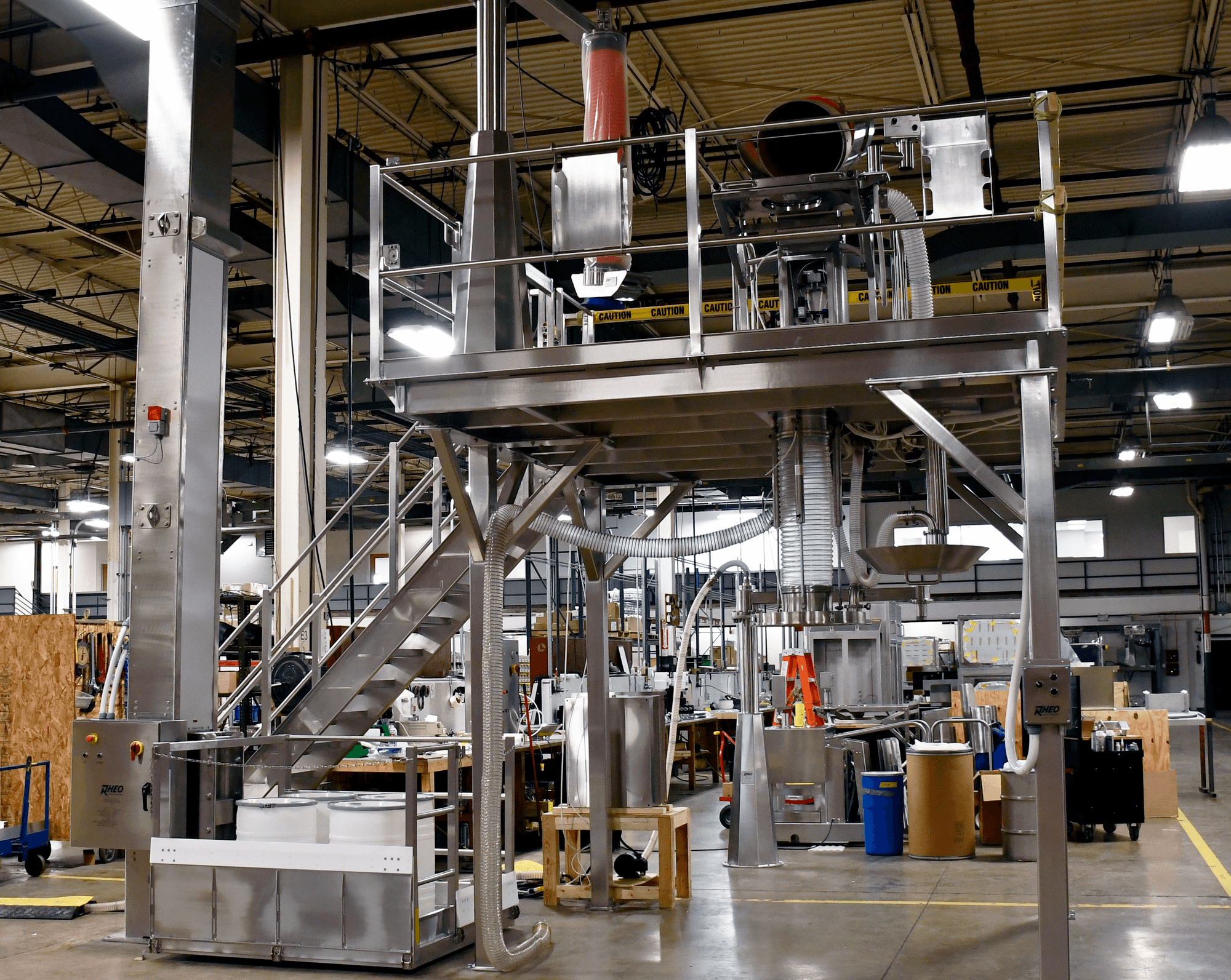

For this project, Rheo designed and fabricated a system to carry out the milling of ingredients (drum and bag stock) as they were charged to blender bins. This system featured an inflatable seal to facilitate a closed system transfer between the comil and bin, as well as a custom lifting mechanism to provide easy access to the comil for cleaning and screen changeout. The entire mezzanine and stairway was designed and fabricated by Rheo to provide a turn-key installation for the customer.

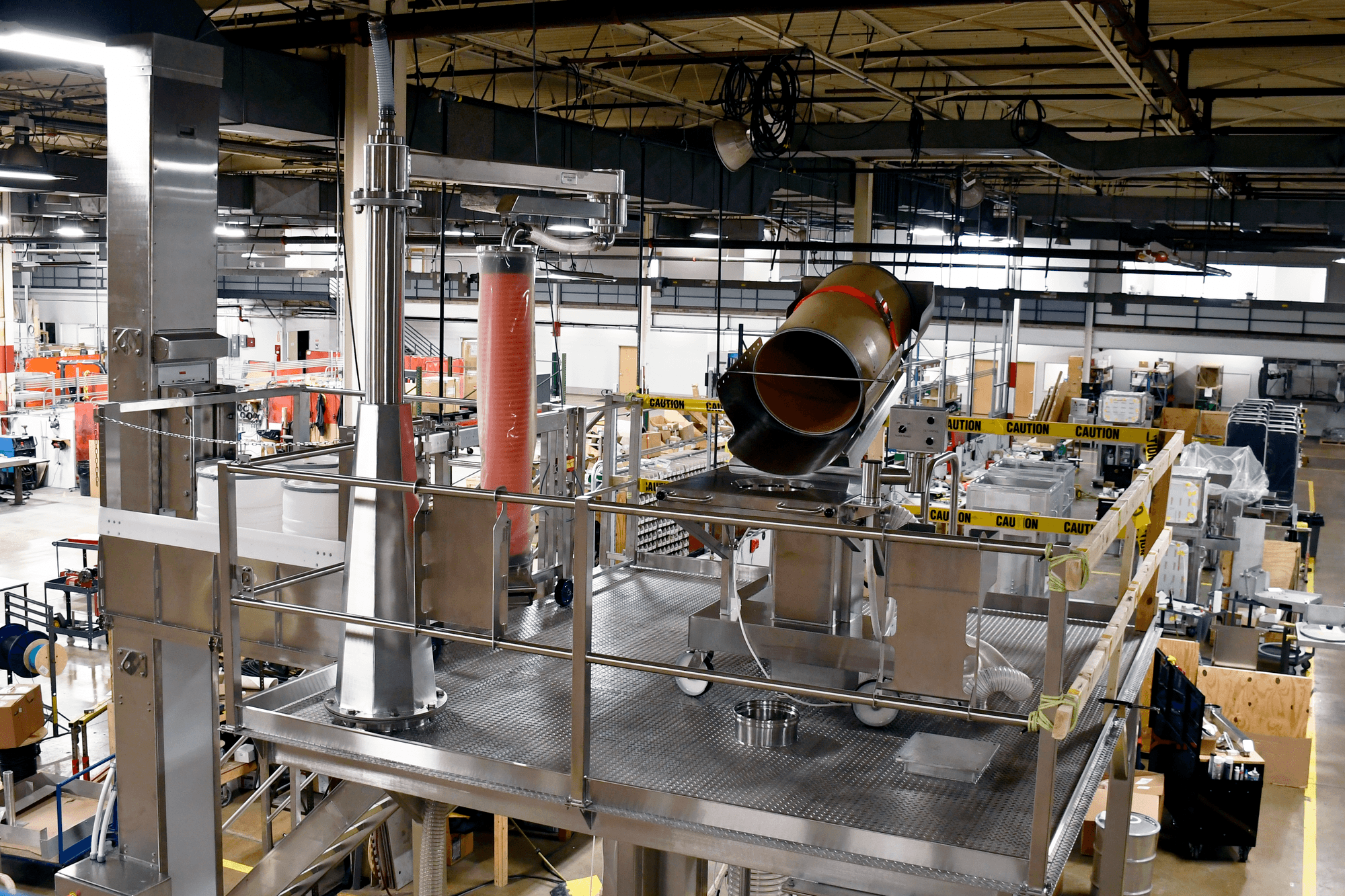

The Material Transfer Station [MTS] is a small footprint workstation that improves operator safety during the material transfer process. A Drum Tipper raises and tips the drum to an ergonomic position for dispensing. A Rheo Ventilation Sleeve is located directly under the MTS table to provide containment during the material transfer process.

The Vacuum Hoist uses an articulating arm to move drums around the platform and to load the drums onto the cradle of the Material Transfer Station.

A Quadro Comil ensures that the material is milled to the desired particle size as the bin is filled. The custom lifting mechanism provides easy access to the Comil for cleaning and screen changeout.

The Mezzanine Platform Structure is a custom engineered platform to facilitate the bin filling operation using an in-floor chute.

The Closed Transfer Docking System consists of an inflatable seal connection and a flexible chute that raises and lowers using pneumatic cylinders. The inflatable seal creates a closed connection around the receiving bin opening.

An integrated control system provides all the necessary interlocks so that each piece of equipment can work together safely.

After successful installation of the system, an additional three setups similar in design were ordered and delivered.