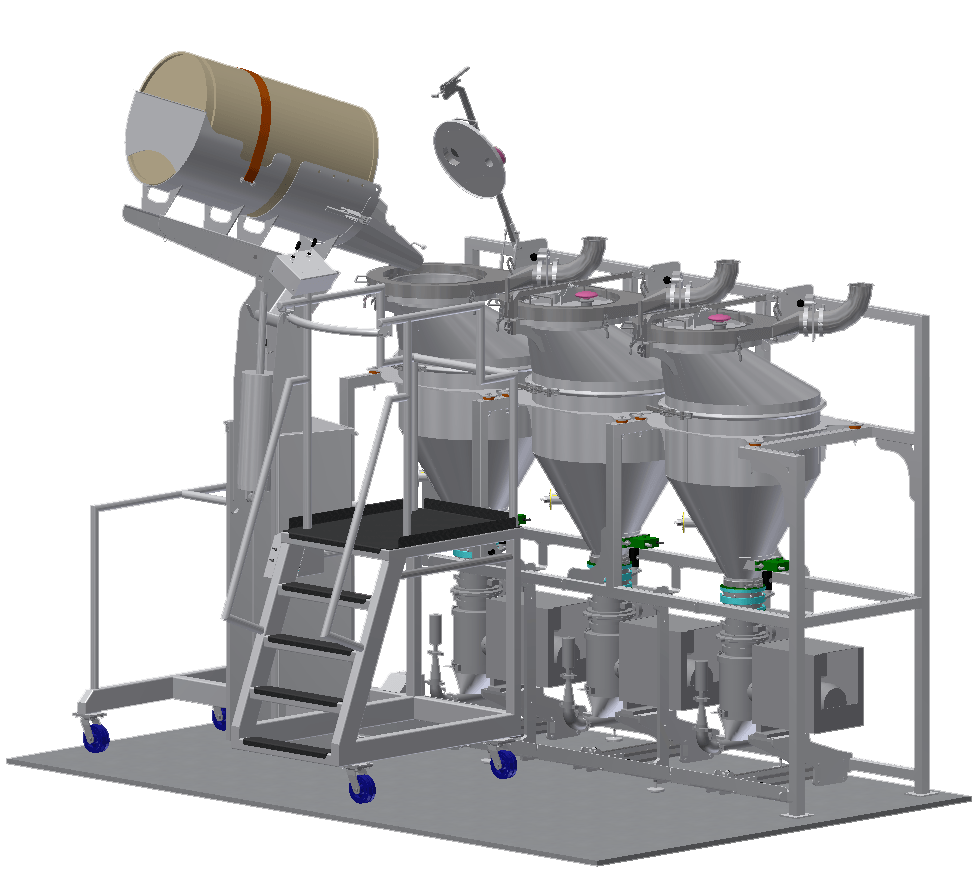

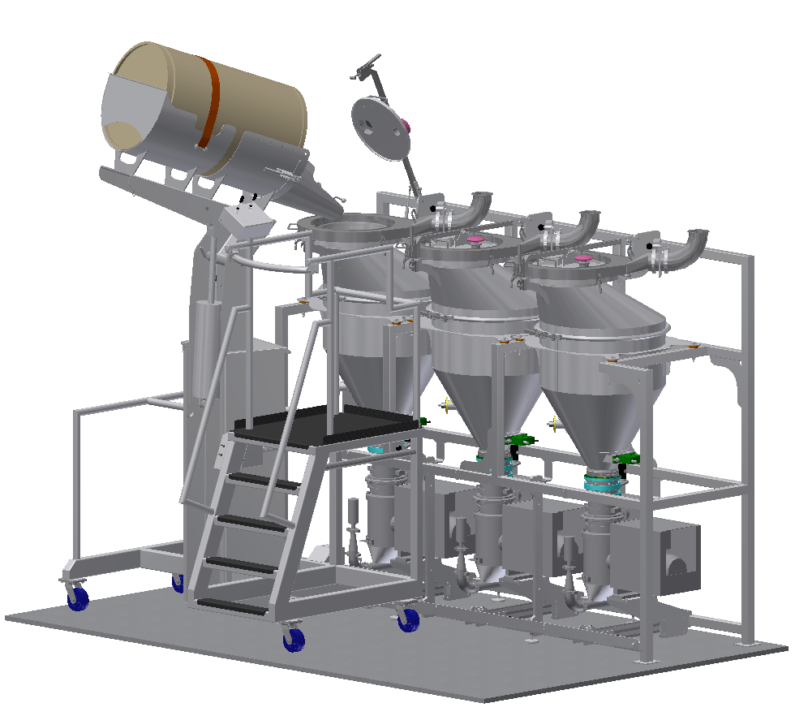

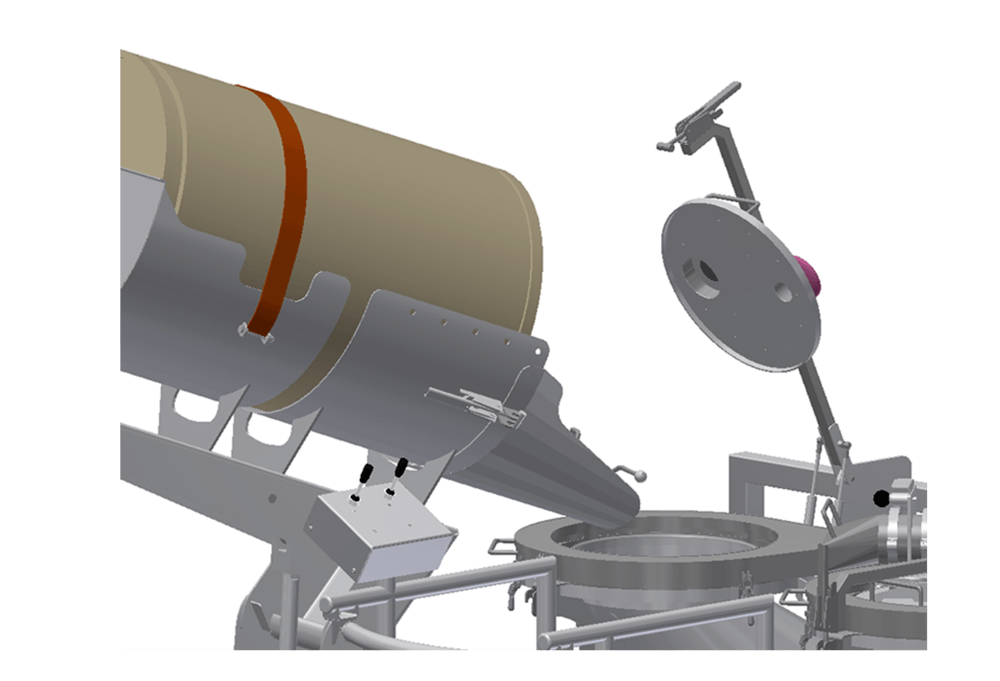

For this project, Rheo fabricated three custom hoppers to feed a vacuum conveyance system. The hoppers were equipped with sight glasses and pneumatic vibrators so that operators could ensure adequate product flow. Rheo Ventilation Sleeves were used in the bin openings for containment during the bin charging. The hoppers were filled from drums using a rail-mounted Rheo Variable Height Drum Tipper with an integrated work platform. The entire Drum Tipper assembly could be quickly positioned at any of the three hoppers and also easily removed for cleaning.

Hopper Filling System

Rheo was asked to supply a customized Hopper Charging System that would provide a safe and contained material handling tool for the new continuous manufacturing, PCMM project at Pfizer. Rheo was asked to customize this system to fit it within the tight work area of the raw material dispensing Pod.

The following video provides some context regarding the Portable Continuous Miniature Modular (PCMM) project:

213230

221312