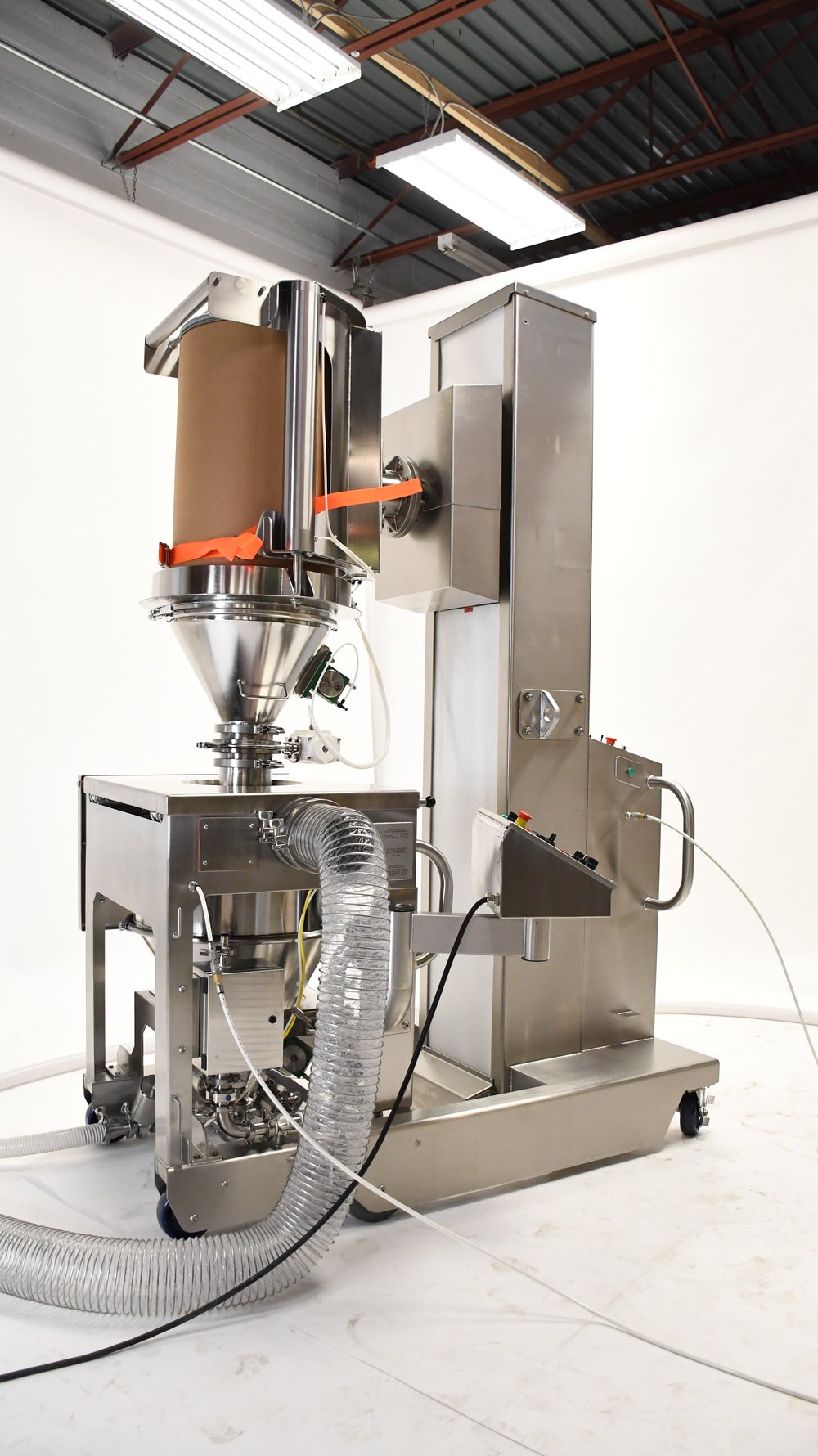

The Material Transfer Station is a small footprint workstation that improves operator safety during the material transfer and weighing process. The operator workstation provides a compact, GMP, ergonomic means of transferring material. This innovative modular system allows the integration of existing and proven technology to achieve containment of airborne particles. There are several pre-engineered modules that can be configured to accommodate a wide variety of process preferences. This modular design offers two levels of containment controls to accommodate the full span of compounds, from non-toxic excipients to highly potent compounds.

The Material Transfer Station allows for either a closed transfer of API or open transfer of excipients. To increase the utility of this equipment, the Material Transfer Station is designed for a quick and easy change over from an open transfer (that uses a full perimeter dust extraction device to capture fugitive dust) to a high-containment system that uses a series of manual butterfly valves to minimize outside contamination.

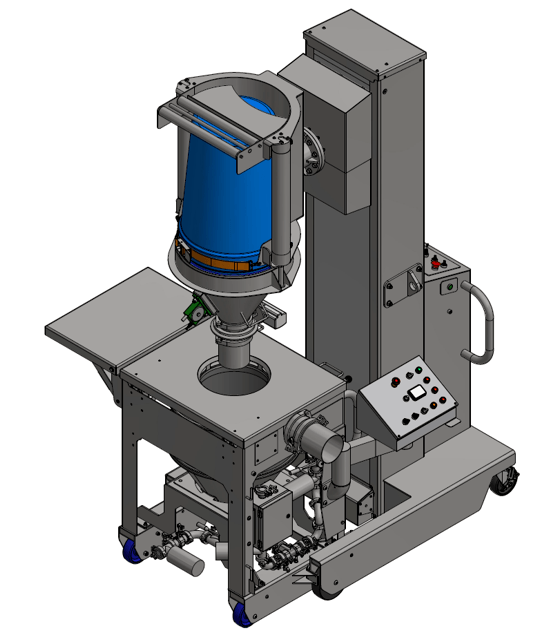

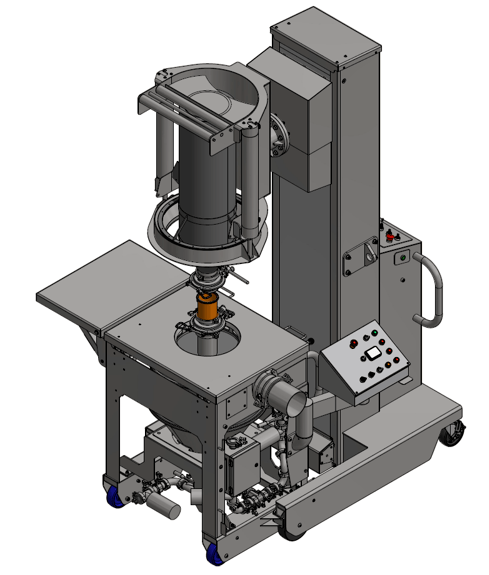

The Drum Inverter consists of a lift carriage and an inversion module with mobile cart. This system provides a robust, GMP, ergonomic means of lifting and rotating drums or canisters to a discharge position. The inverter is operated using pneumatic controls located on the main panel of the machine’s control housing. The Drum Inverter is designed to handle standard drums, using a compression funnel and an actuated butterfly valve, or canisters that have a funnel and manual valve already built in.