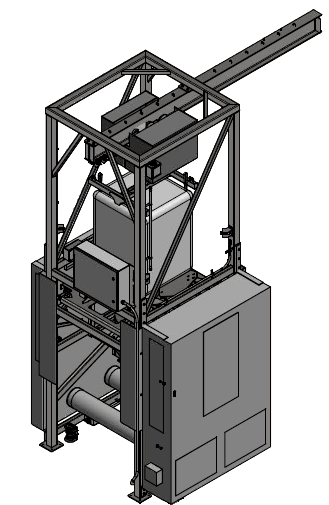

For this project, Rheo Engineering designed and built an integrated system for transferring both salt and dextrose from bulk bags into process vessels through a high shear induction mixer. This turnkey system featured a Hoist, a Docking Station, a K-Tron Screw Feeder, and an Inline IKA Disperser.

The Hoist provided a fast and simple docking process lifting the bulk bags from the ground floor up to the second floor. Ultrasonic sensors communicate with the control system to lift and position the bulk bags into the Docking Station.

The Docking Station consists of a powered bag clamp, dust extraction, pinch valve, and bag tensioning. The powered bag clamp seals the bulk bag liner neck to the transfer chute with integrated dust extraction to provide containment. The bag tensioning cylinders stretch the neck to ensure proper flow of solids from the bag. The pinch valve squeezes off the neck of the bulk bag controlling the flow of the solids. A cross flow exhaust system provided additional dust extraction.

The materials are then fed to the K-Tron Screw Feeder which controls the introduction of the solids through a transfer chute to the IKA Disperser located in the clean room on the ground floor. The IKA Disperser is an inline high shear mixer that disperses product into the liquid stream as it recirculates through the process vessel until the desired solution blend is achieved. A transfer rate of 3000 kg/hr of material with a liquid flow rate of up to 150 GPM was achieved with mixes having a concentration up to 70%.

A small additions hopper was integrated into the flow path on the clean room level. The entire transfer process had Clean In place and Dry In Place capability.