Bulk Bag Unloading Station:

SoliValve® with Powder Induction System

Choose a configuration below.

Bag Connection and Flow Aids

Transfer Modules

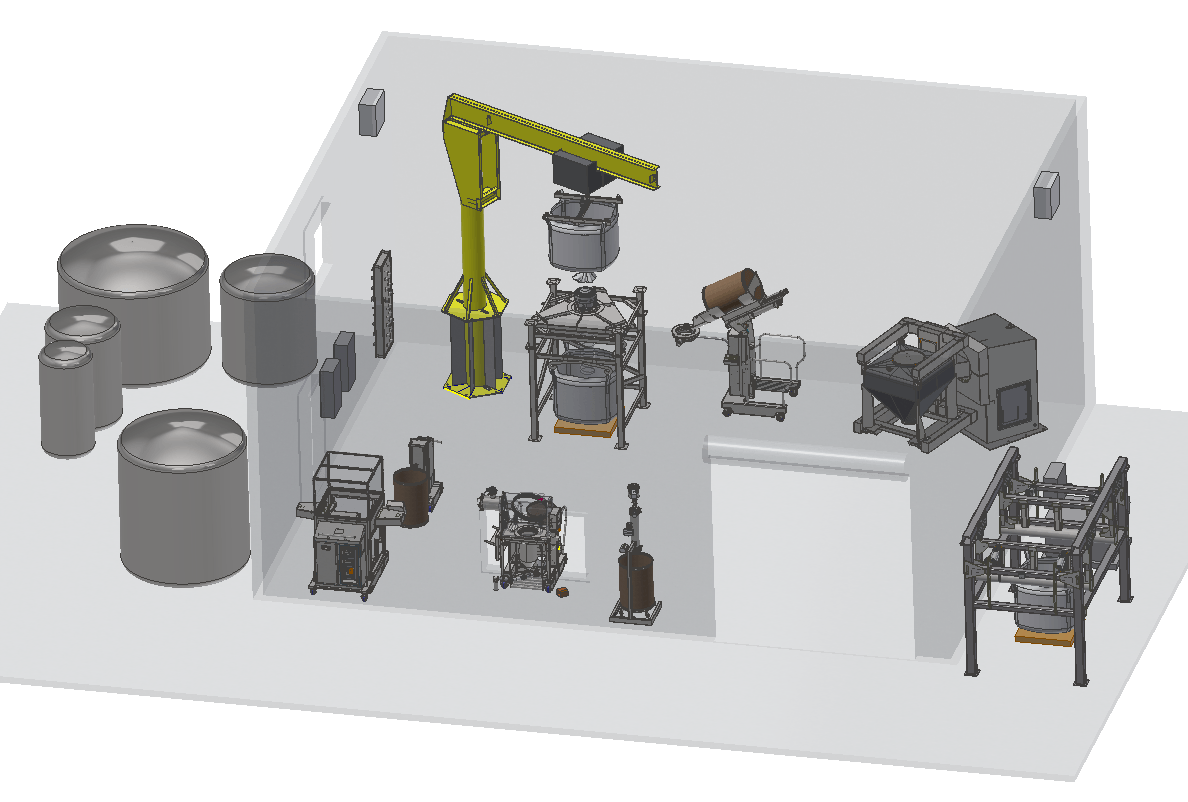

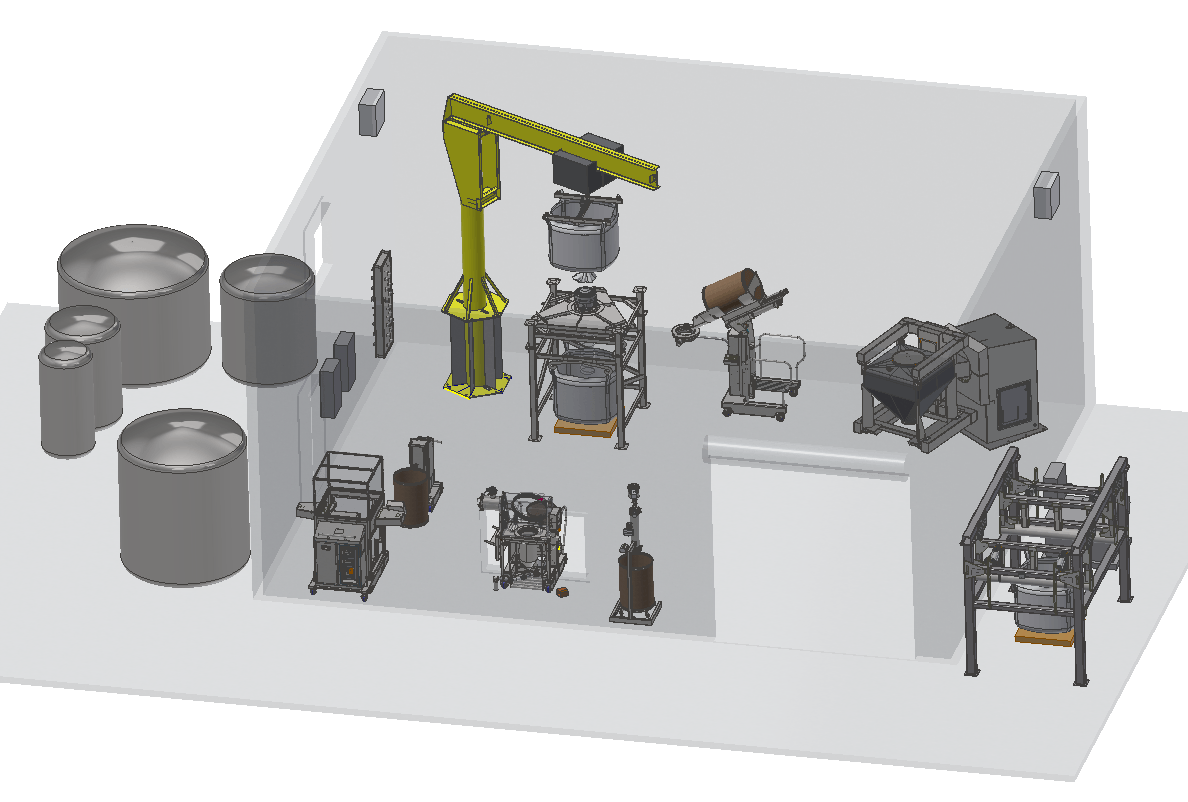

Bulk Bag Unloading Station Configurations

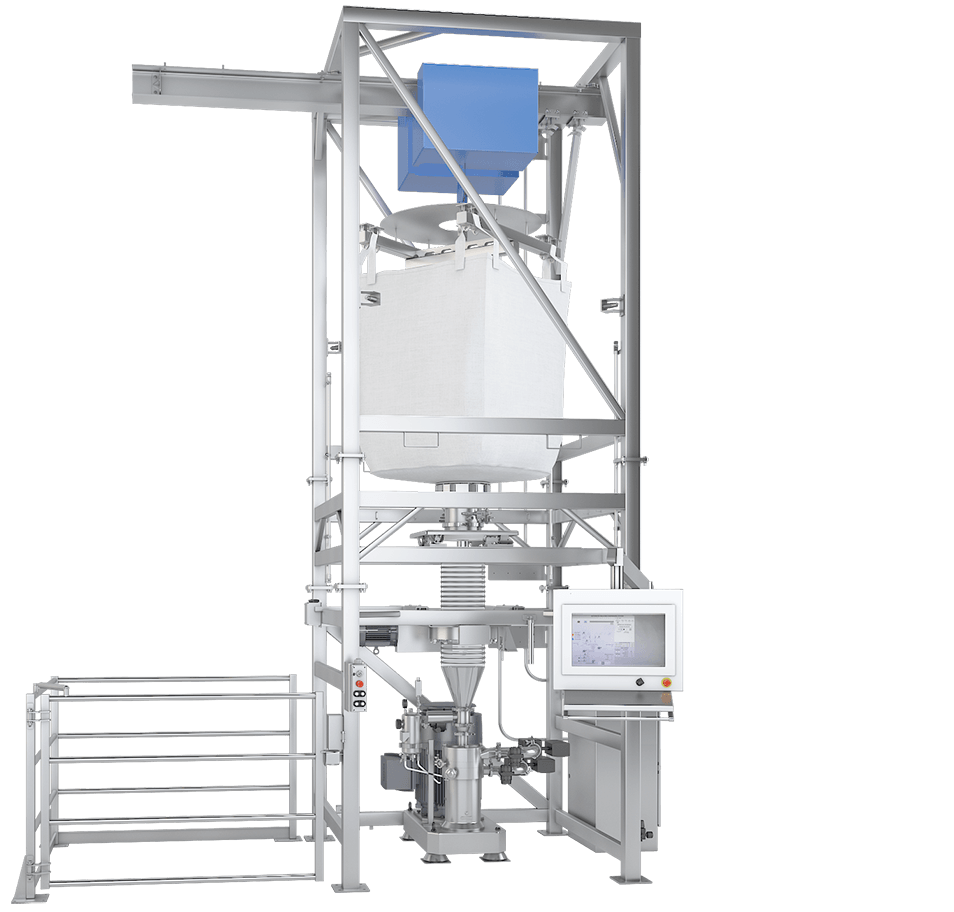

BBUS - SoliValve® with Powder Induction System

Transferring and mixing bulk solids to liquids in vessels can raise a number of process challenges; powder clumping when introduced to the solution, agglomerations on the vessel side-walls, extended downtime for cleaning between batches, the need for accurate dosing, and maintaining efficient mixing times.

The Rheo Bulk Bag Unloading Station: SoliValve® with Powder Induction System configuration offers the following benefits to address these challenges:

- Liquid and solids are simultaneously introduced and immediately mixed in powder induction tooling before transferred to tank, eliminating powder clumping and side-wall agglomerations.

- Integrated PAT and sensor controls material input rates to achieve proper concentration and a homogeneous mixture.

- Powder Induction System achieves mixing concentration 5-20X faster than traditional agitator.

- Batch Production Time (bag unloading through mixing): down to 15 minutes

- Bulk Powder Transfer Rate: 350 kg/min

- Weighing and Dosing accuracy: +/-500 g

- Verified CIP Cleaning Process: Set-up: 5 minutes + Rinsing: 20 minutes + Drying: 30 minutes = 55 minutes

Rheo hosted a product spotlight webinar on the Rheo Bulk Bag Unloading Station. See additional information and request materials here.

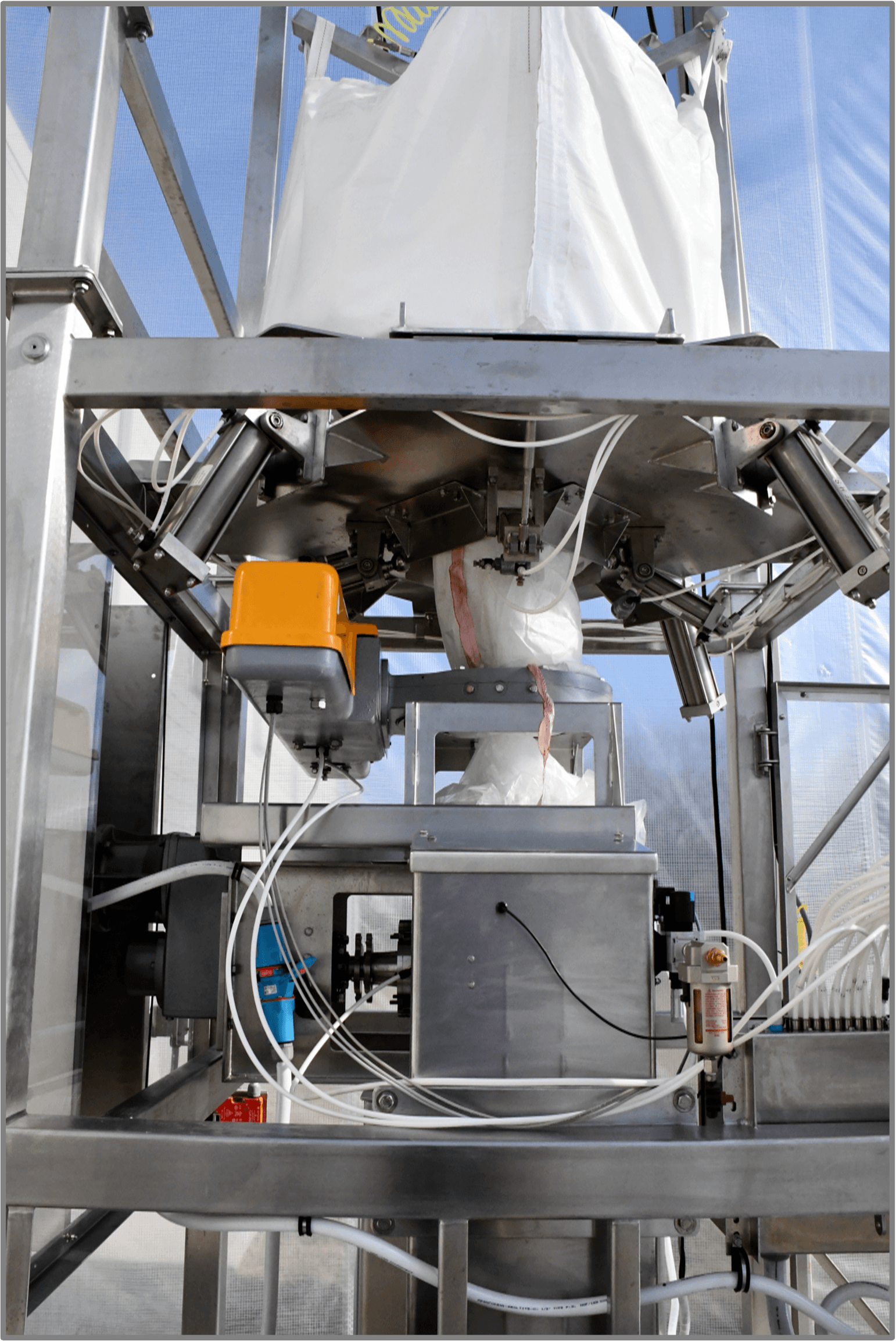

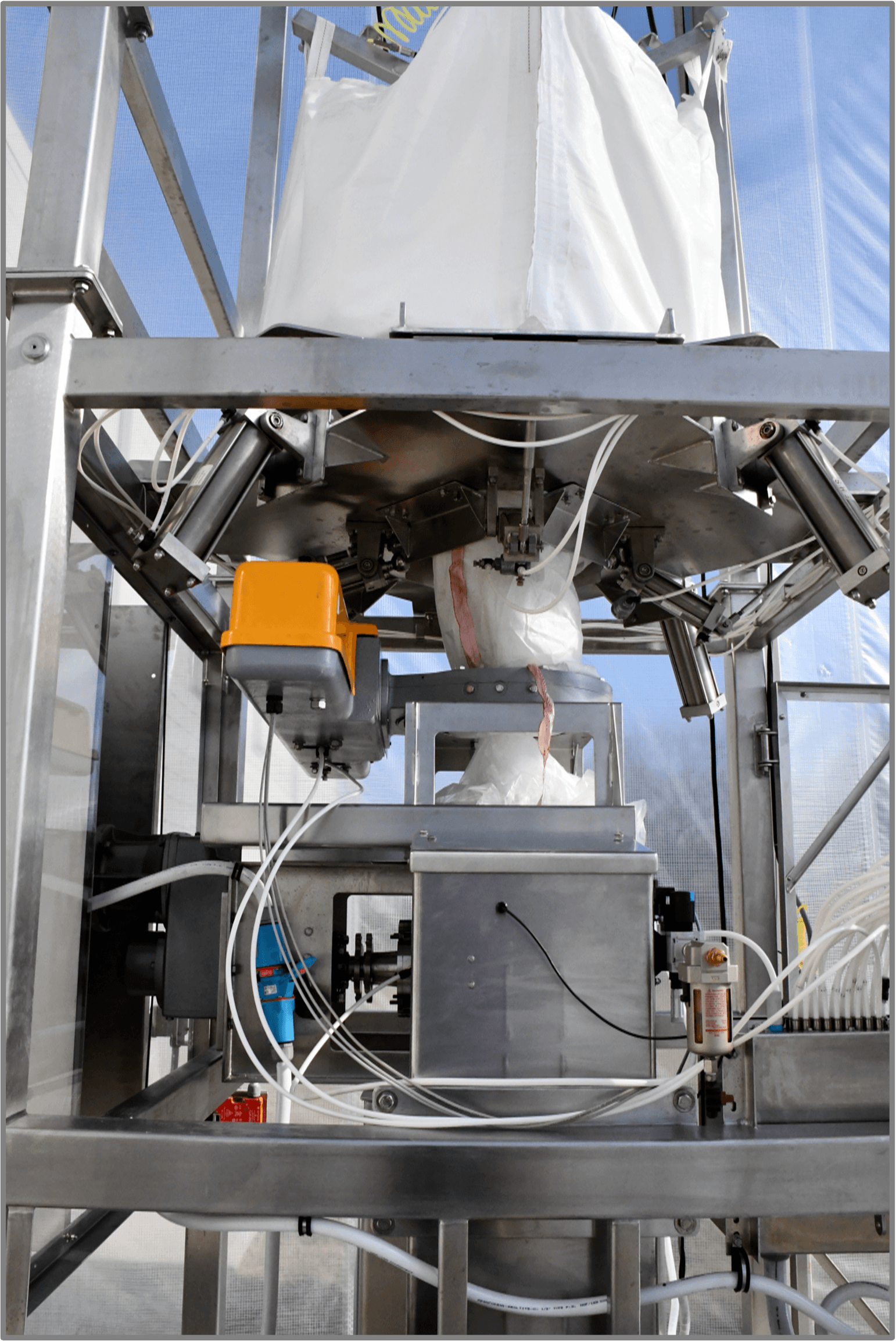

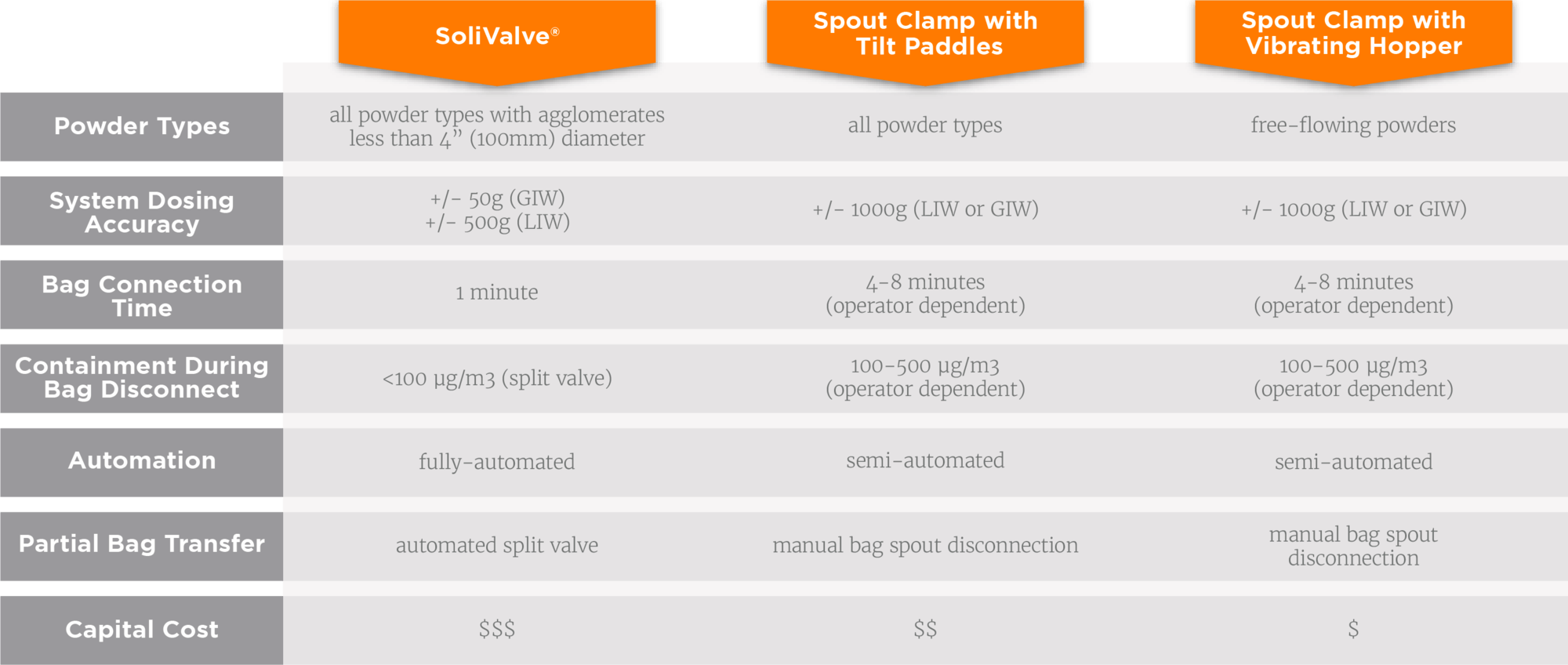

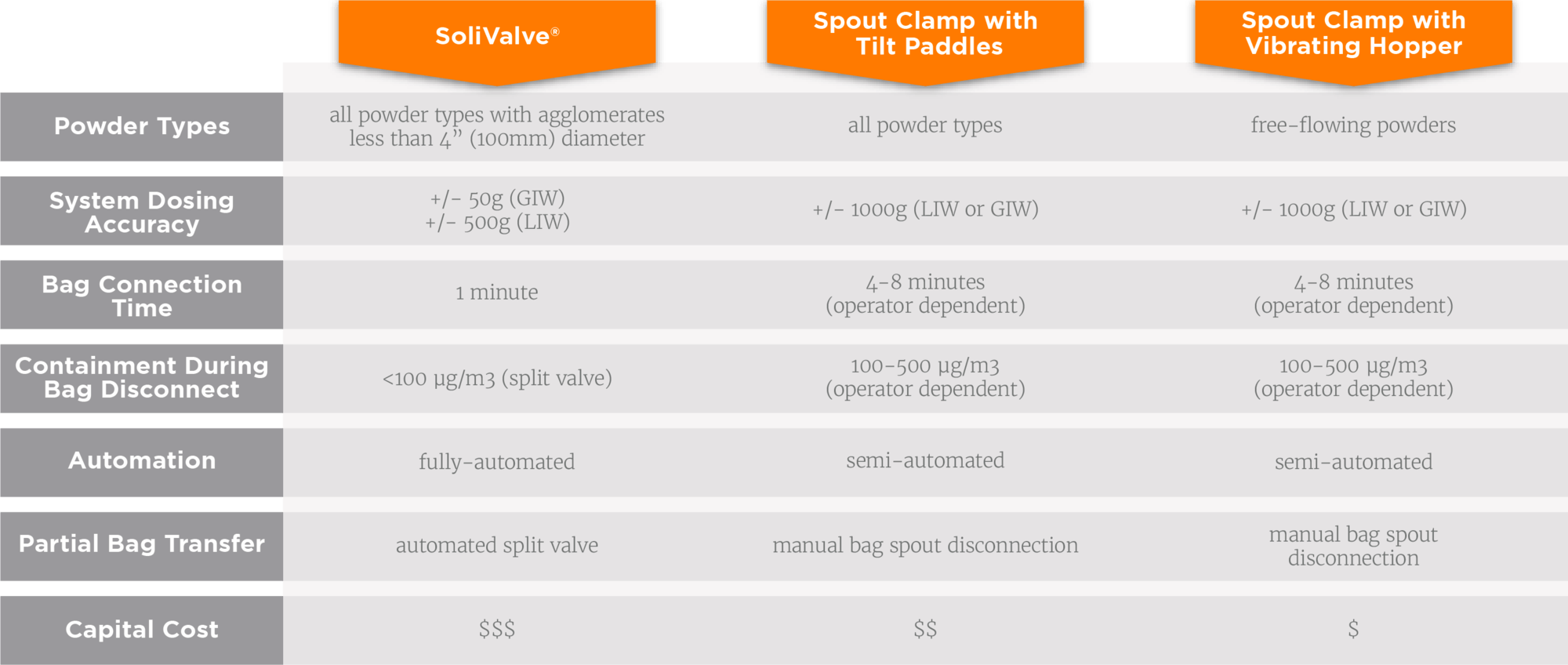

SoliValve®

The SoliValve® 250 overcomes the traditional issues encountered with the 30 years old traditional cone valve. It allows fully automatic and contained handling of big bags, containers, and drums. The SoliValve® 250 doses the material vertically from the storage container, allowing re-closing of partially empty vessels and changing to another ingredient without residual material in the dosing hopper. The SoliValve® 250 can achieve containment levels of less than 100µg/m³ and can reach a dosing accuracy of +/- 20g.

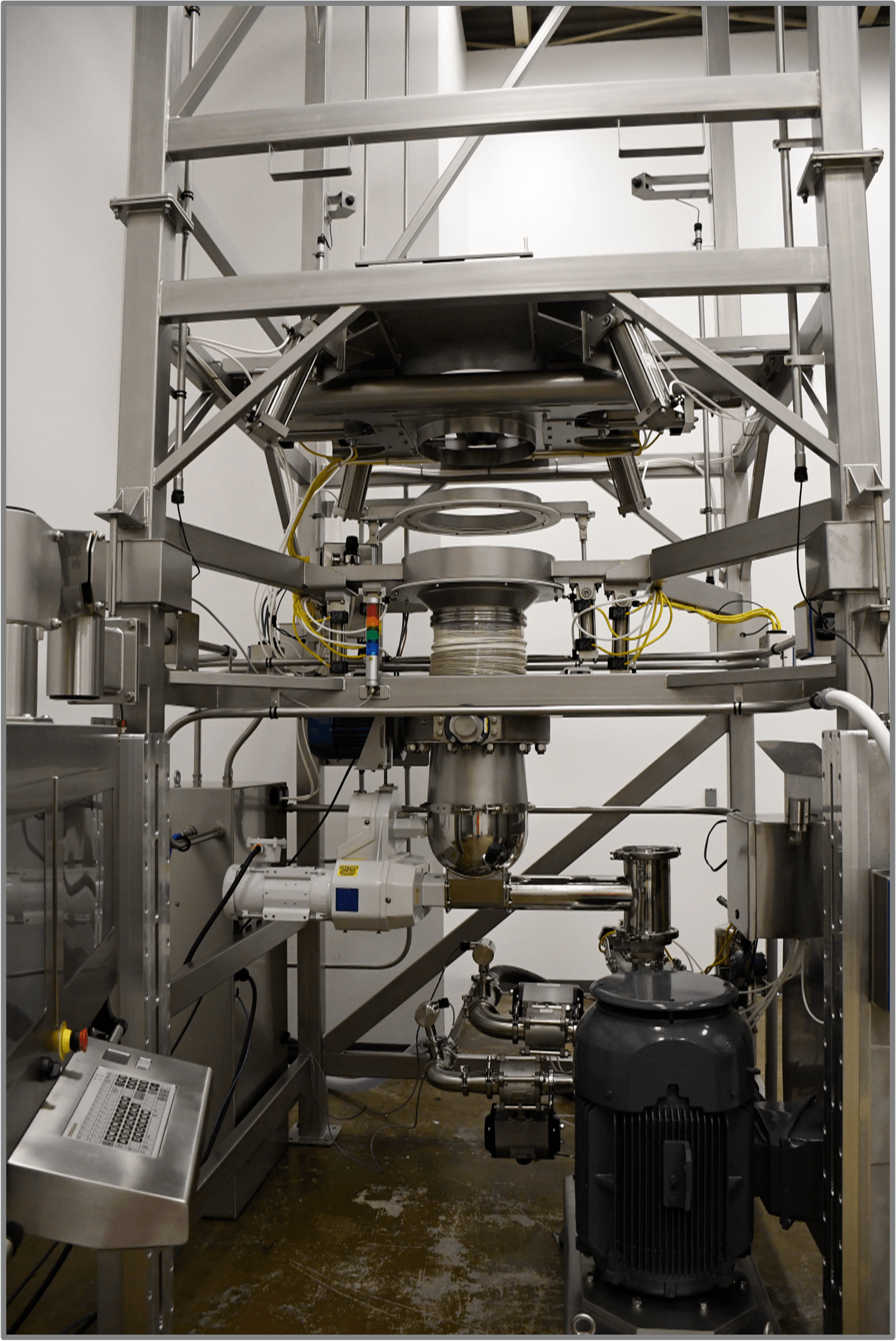

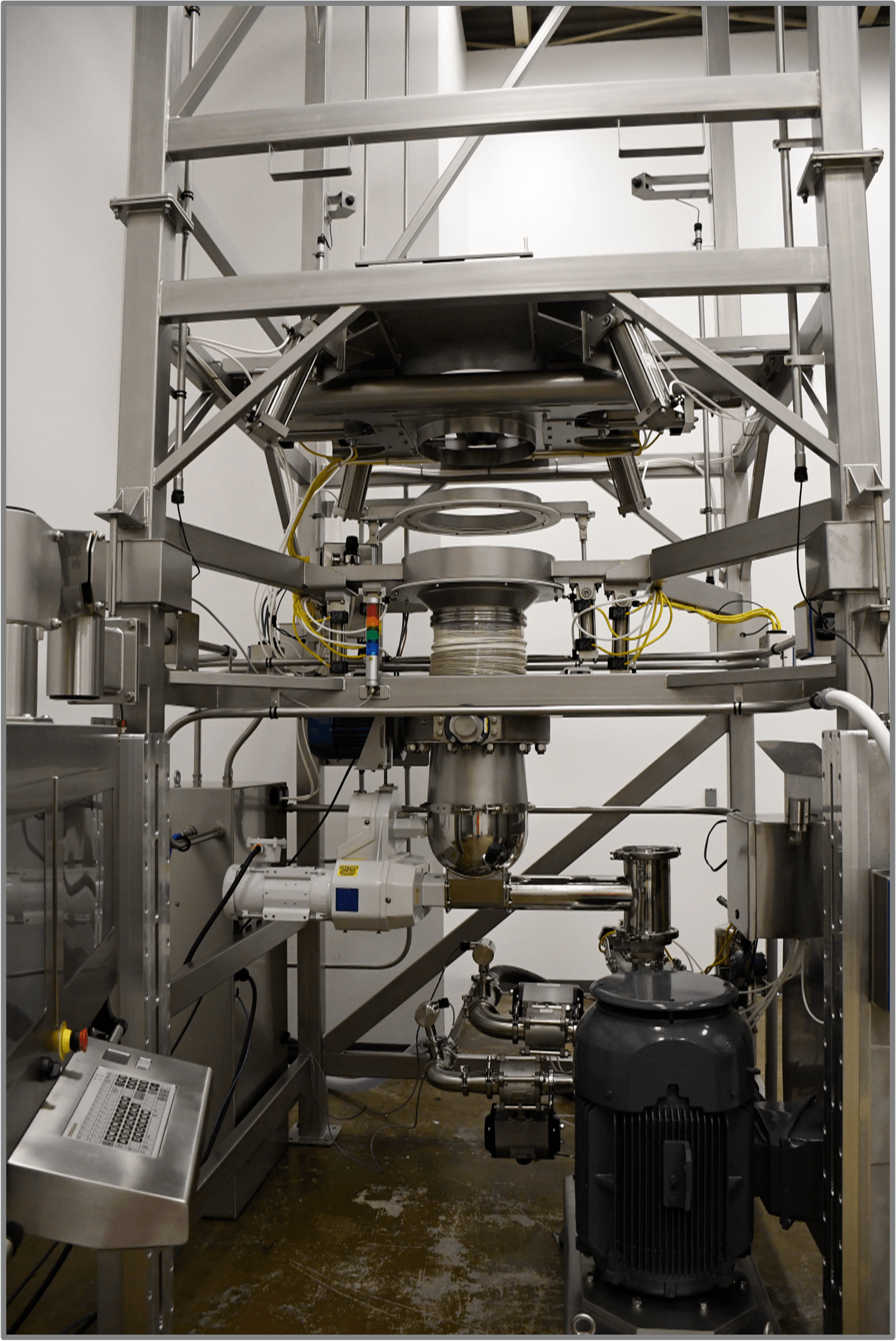

Powder Induction System

The integrated powder induction system allows the bulk bag to unload into a disperser system that can mix the product with a solution and pump it directly to, or recirculate through, the receiving vessel. Minimal dry cleaning areas improve the mix times for transferring to liquid vessels.

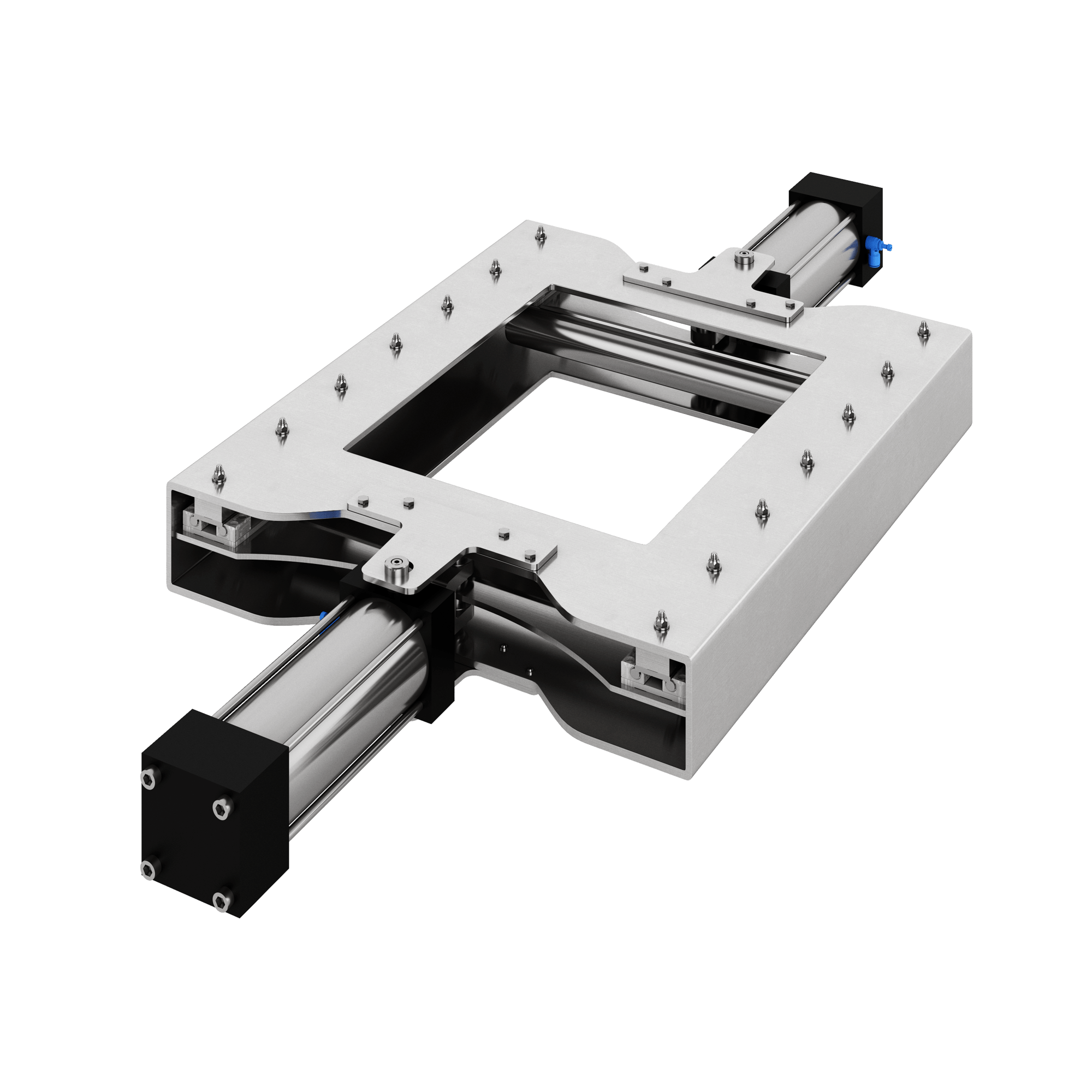

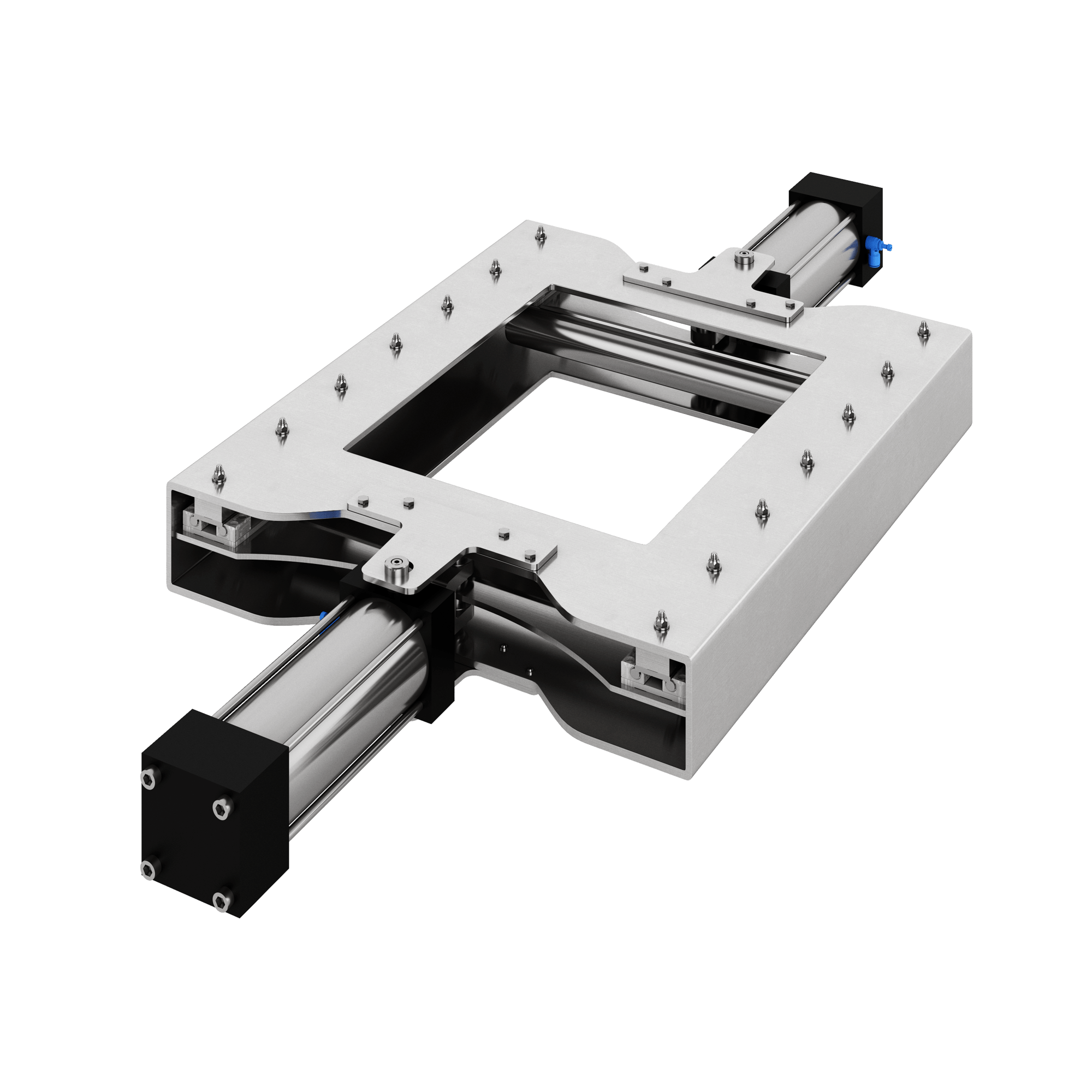

Transfer Module

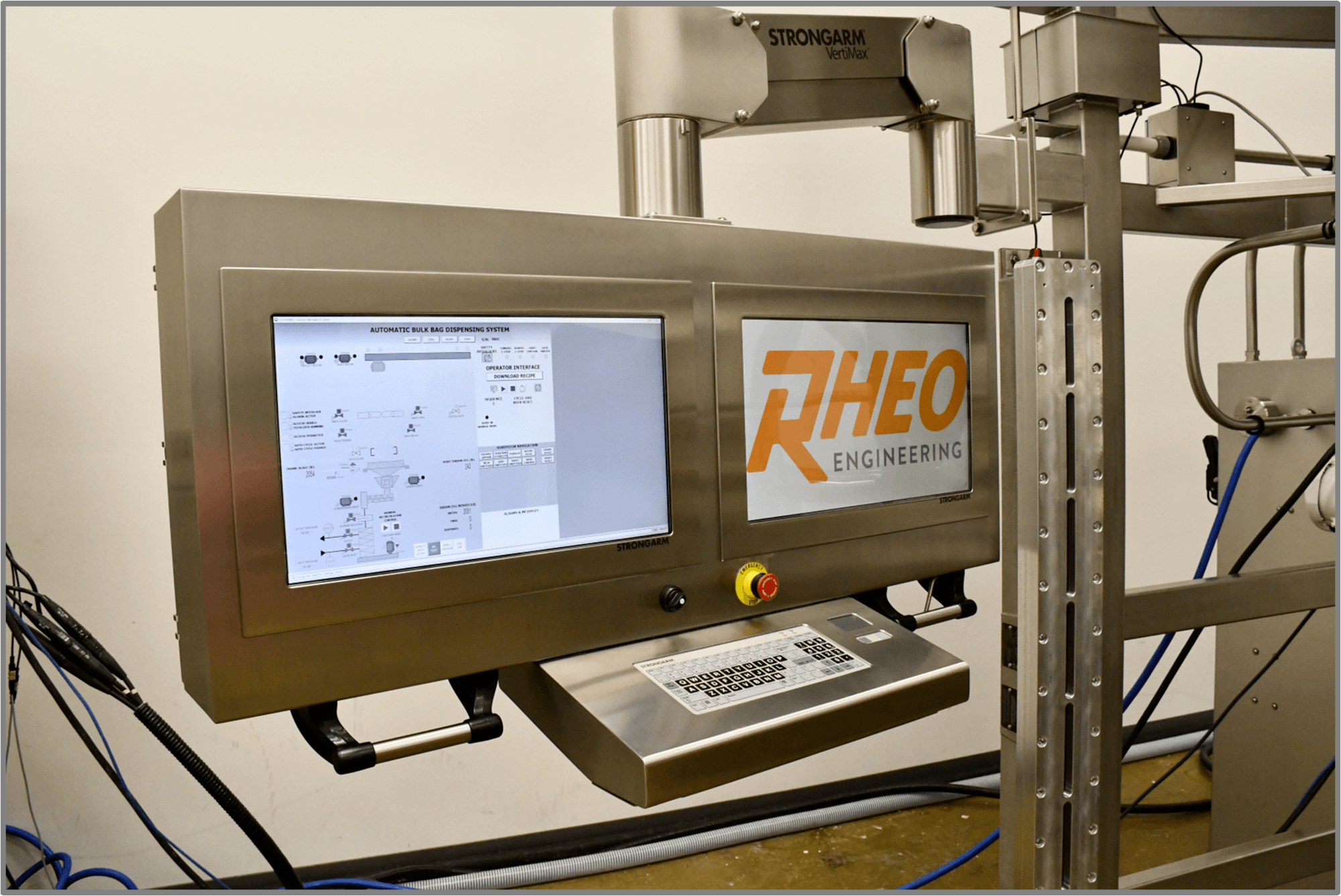

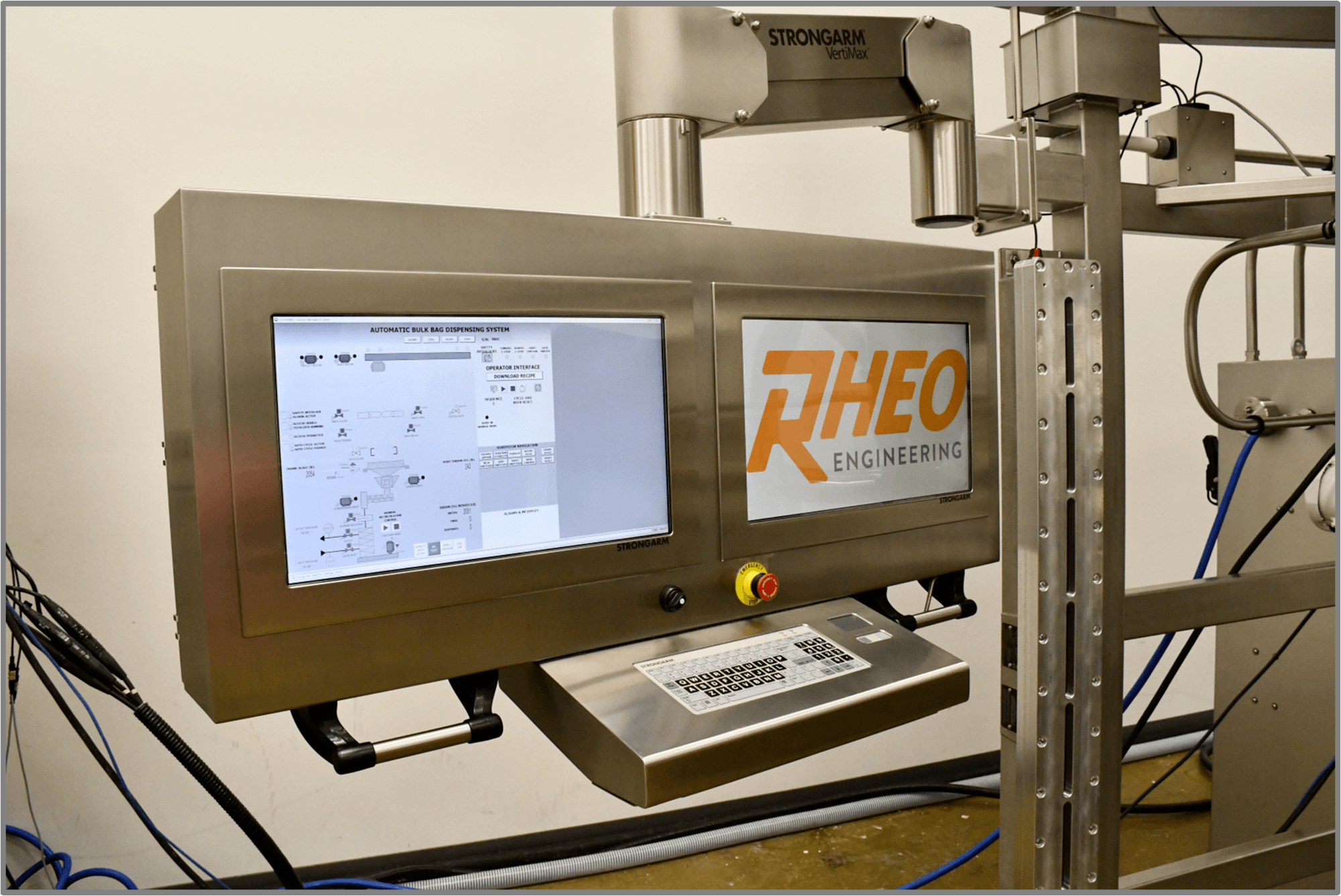

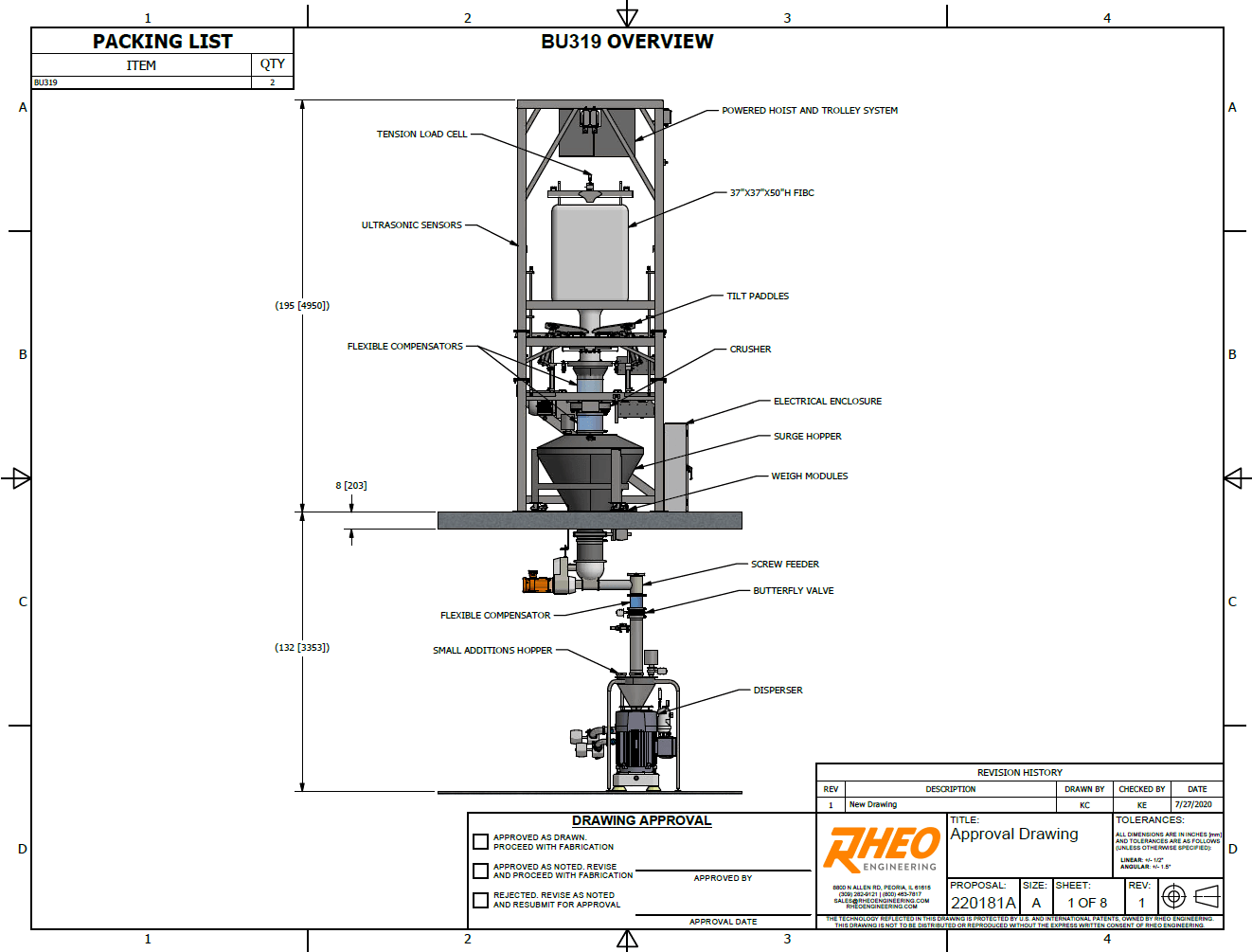

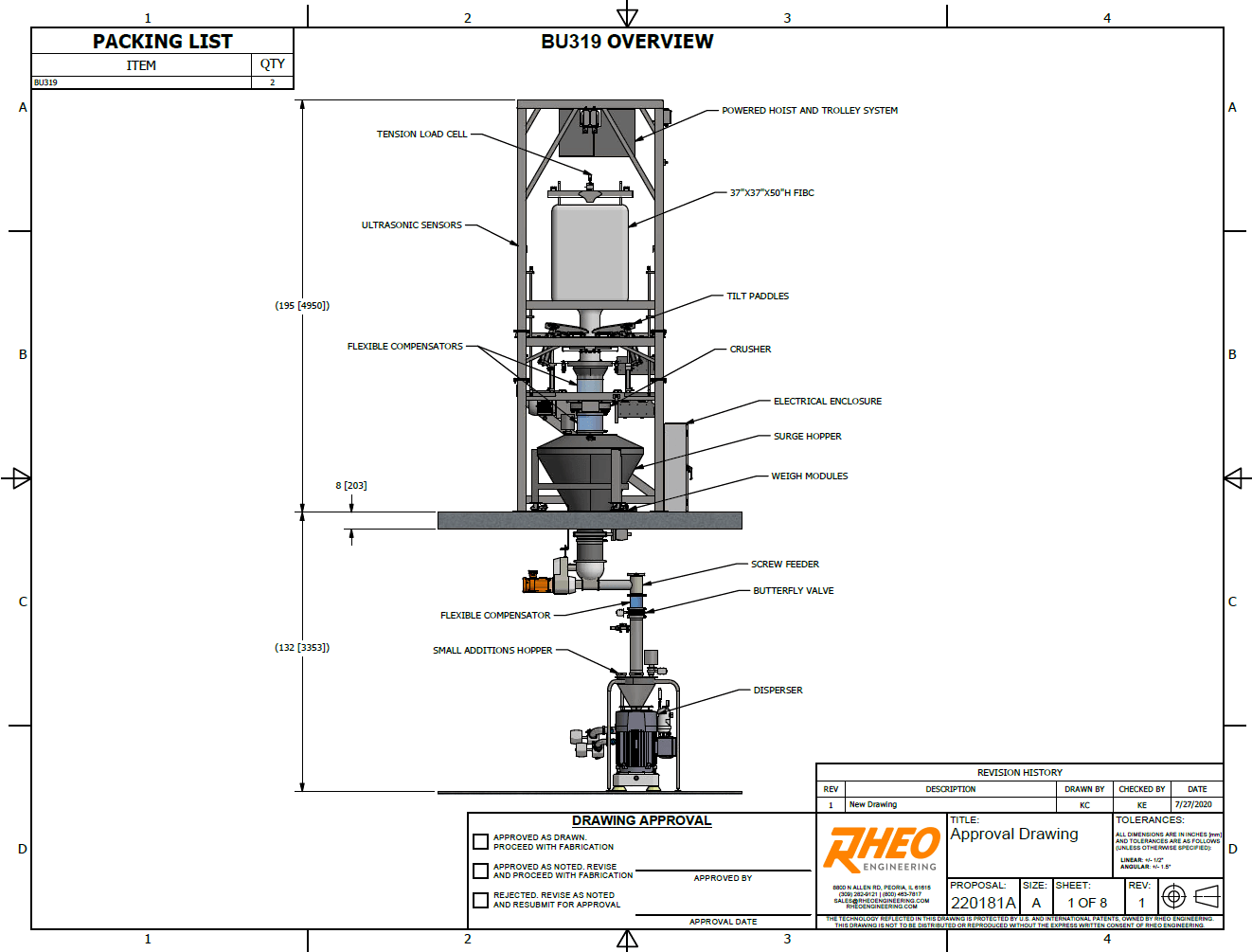

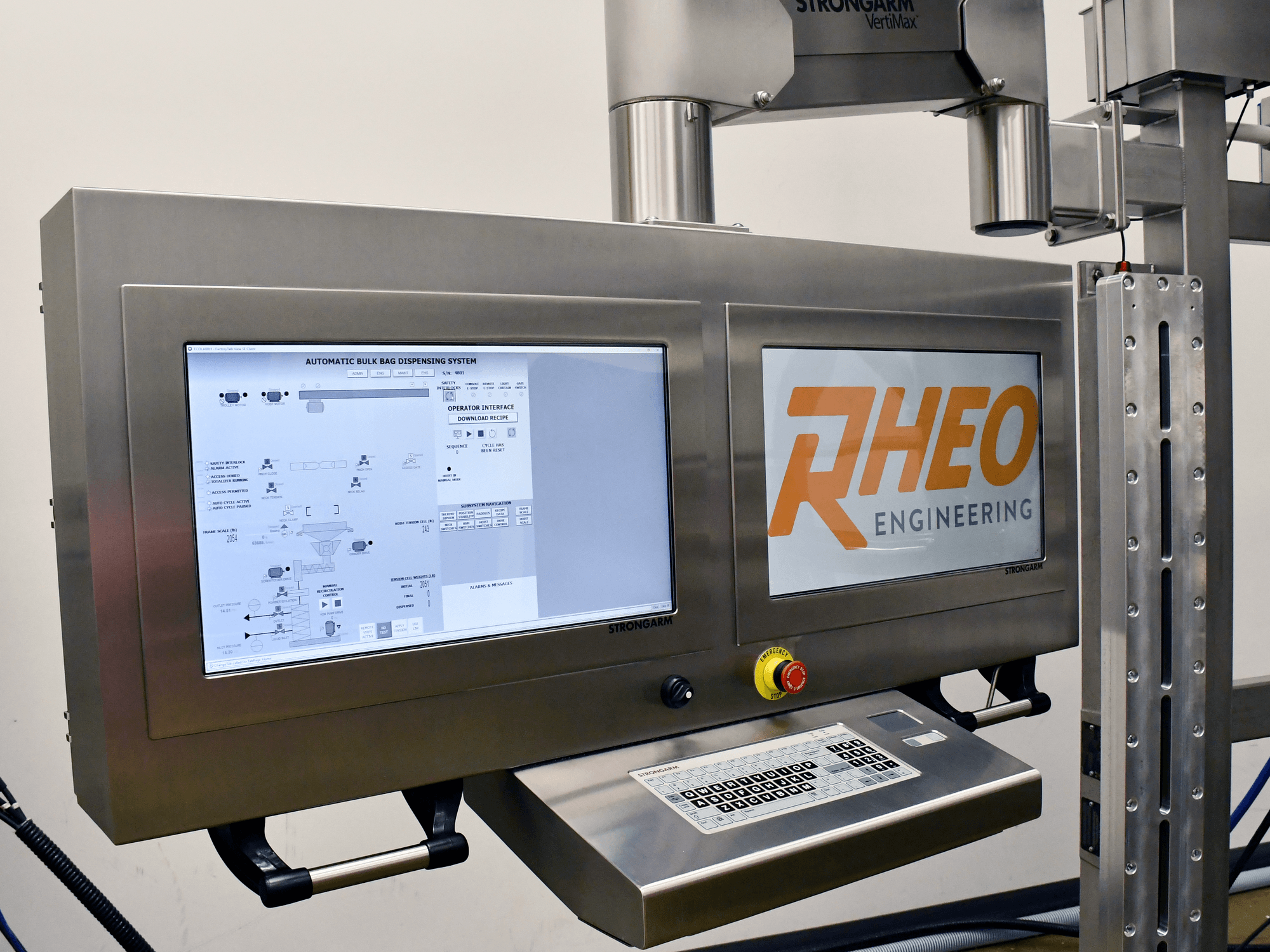

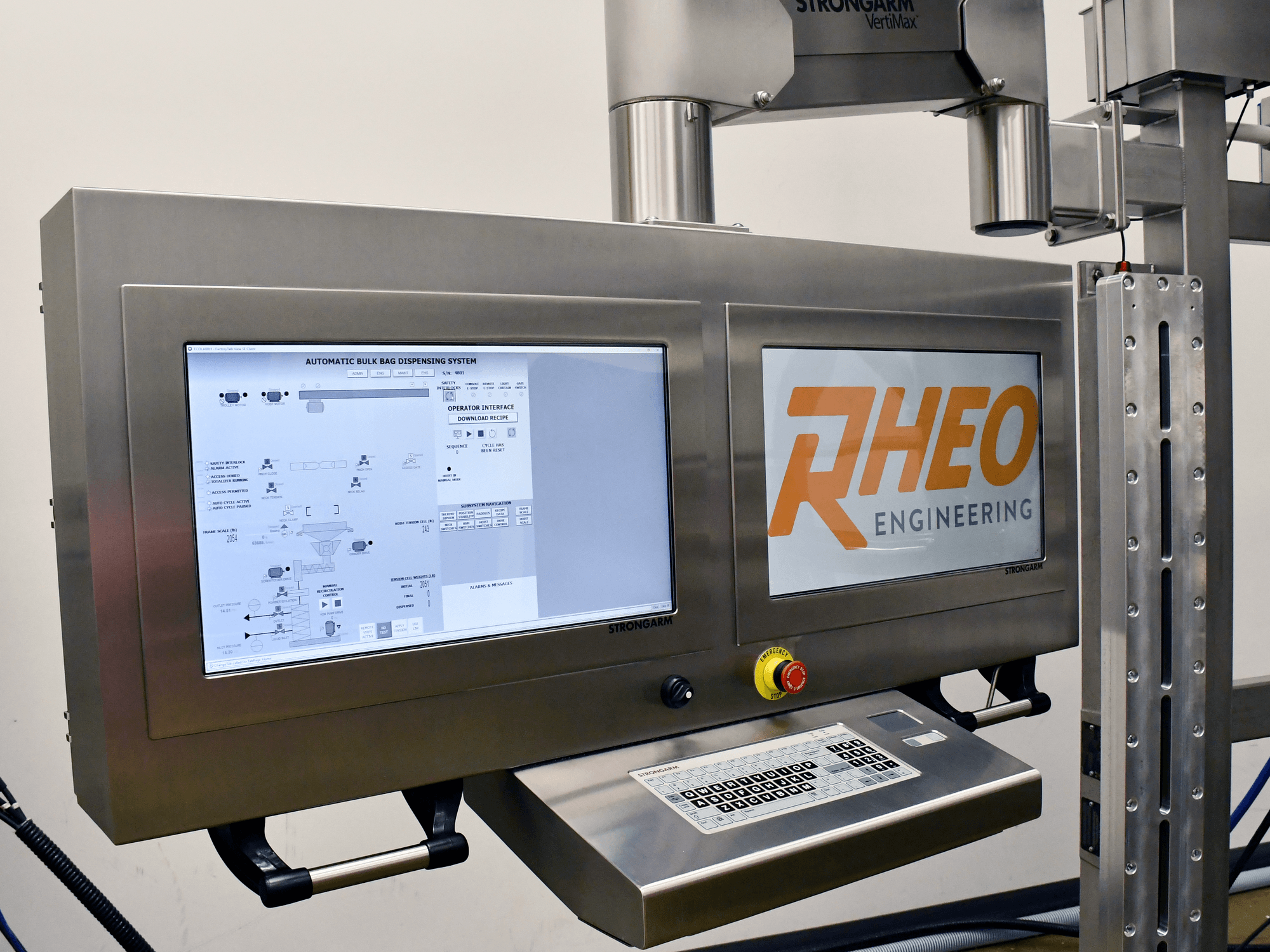

HMI Controls

Automated System

Platform Load Cells

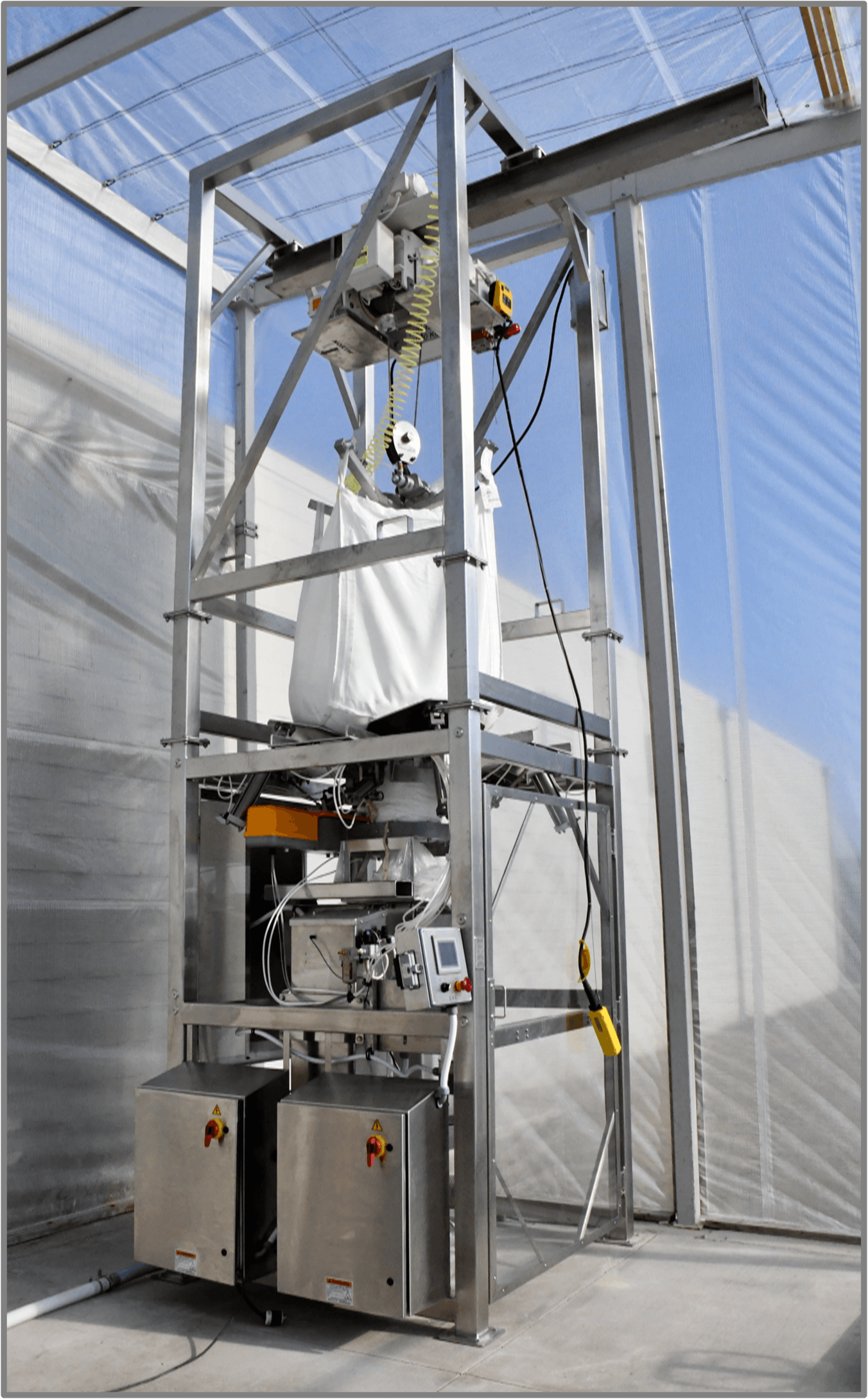

Bag Loading Zone

Inline Process Component

Bag Connection and Flow Aid

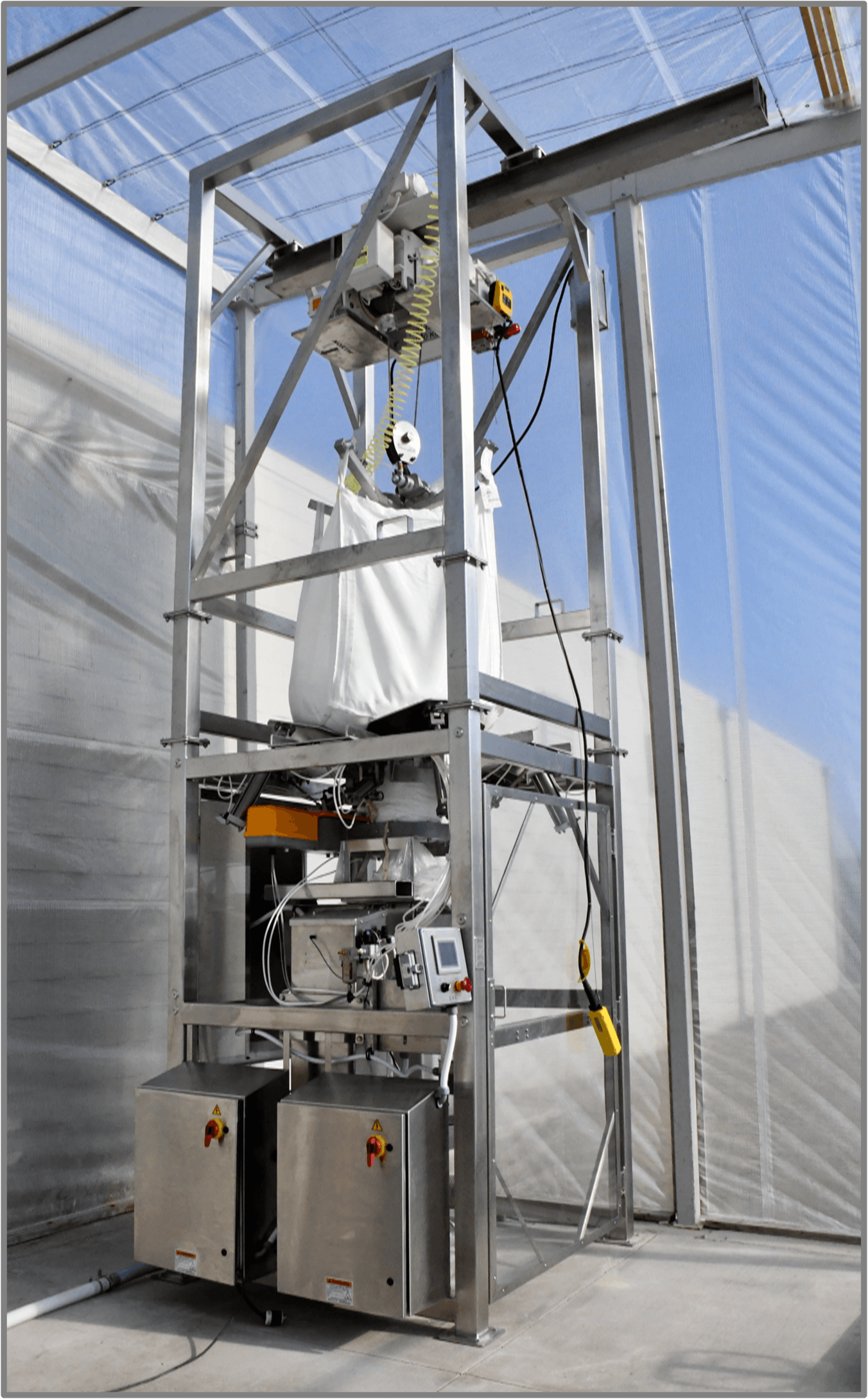

Floor Mount Frame Structure

Bag Positioning Sensors

Fully Automated System

Tensioning Load Cells

Hoist and Bag Hanger

Bag Connection and Flow Aid Comparison

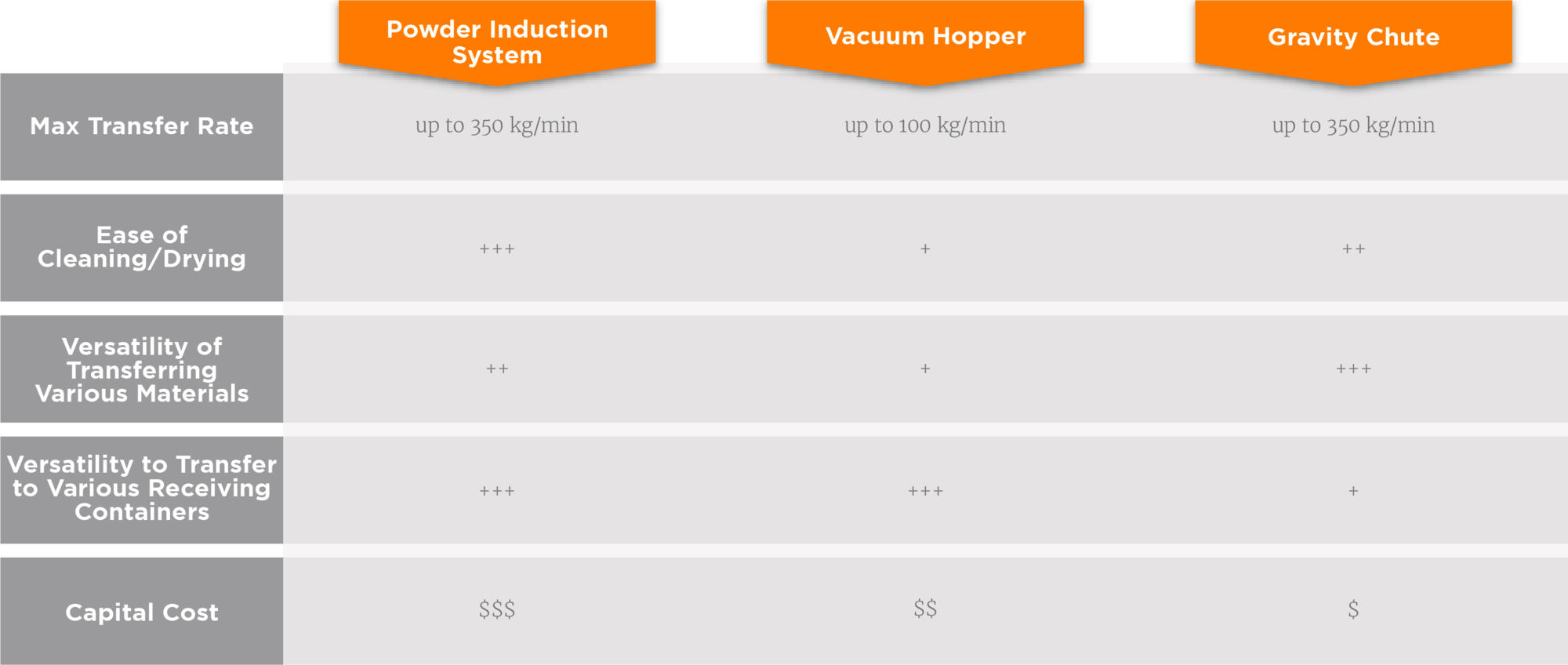

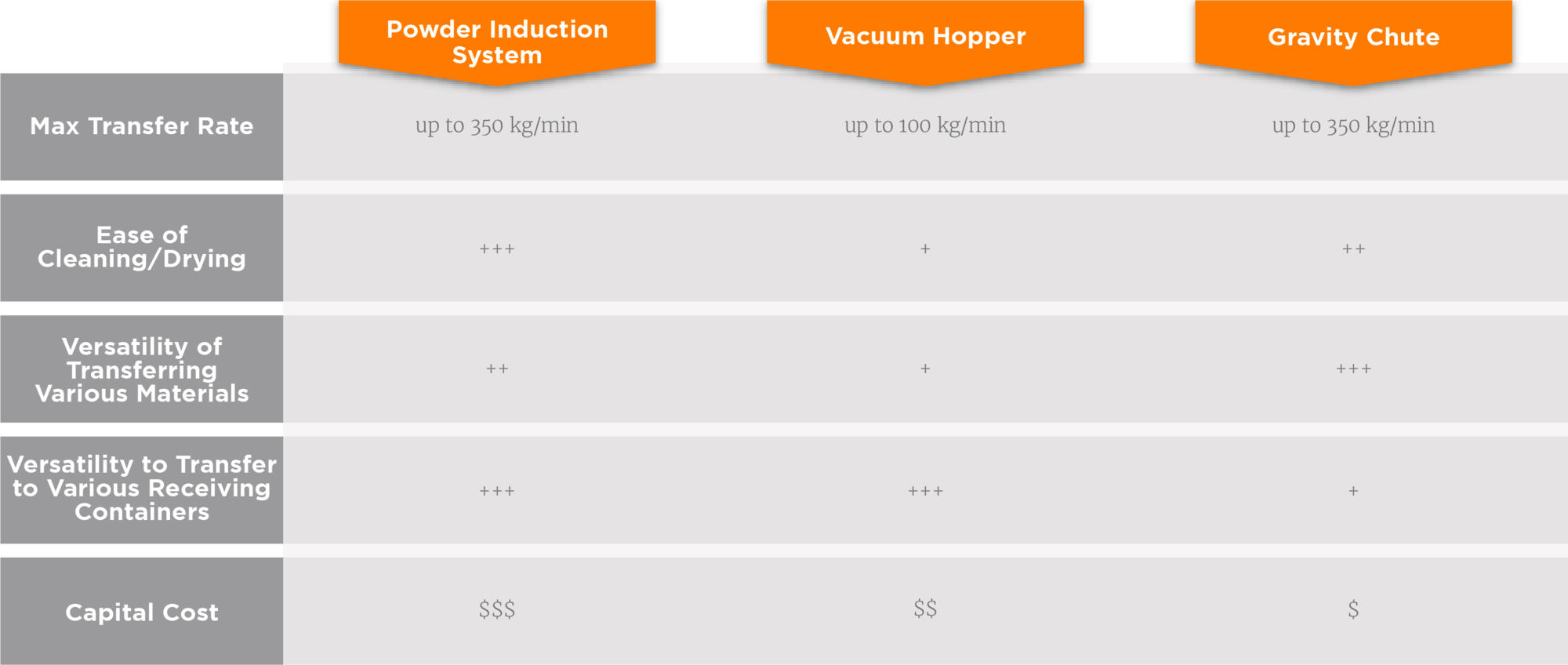

Transfer Modules Comparison

Testing Center

Bulk powder handling can be a challenging process and there are many factors that lead to the optimal solution. We can handle the risk for you! Our Testing Center is equipped to test your materials, allowing us to design the best solution for your specific needs. We don’t just sell a product – we sell a solution.

Reach out to your Regional Sales Manager to discuss the testing of your next bulk powder handling project.

Customizable

We will design custom configurations for your specific process. The Rheo design library allows our team to efficiently tailor our products to meet the specific requirements of each application. During the design phase, the Rheo engineering team analyzes the application to develop a custom and comprehensive material handling solution. By using standard options as well as custom-designed features, a GMP operator-centric design can be achieved.

Advanced Features

Integrated Weighing

An automatic weighing system can be designed into the Bulk Bag Unloading Station configured as either a gain-in-weight (GIW) or a loss-in-weight (LIW) system. The SoliValve® or a pinch valve will automatically adjust to slow down and stop material flow to hit the target weight and to allow for partial bag unloading.

Inline Process Components

Crushers, mills, or screeners can be easily integrated in-line to help with material flow and to reduce a process step.

CIP Spray Devices

Spray devices can be added to the product contact areas to ensure the system is fully Cleanable in Place (CIP). Our GMP retractable spray device fully retracts out of the product stream during powder transfer to ensure no blockage or retention and only extends during the cleaning process.

Water coverage of the CIP system can be validated (Riboflavin) during a Factory Acceptance Test.

Controls and Automation

Typical controls for the Bulk Bag Unloading Station include a touchscreen HMI that can be connected to your plantwide network. Simpler control options are also available.

Sensors can be integrated into the system to recognize when product flow has slowed or stopped which can trigger flow aids to turn on or warn the operator to intervene.

Pinch Valve

Controlling the flow of the bulk powder stream can be a challenge to the unloading process. The pinch valve is often used in conjunction with the spout clamp to control flow. It is designed with high powered cylinders to quickly and reliably cut-off the powder stream, capable of achieving dosing accuracy within +/- 1 kg.

Common Specifications [customized per application]

| Load Capacity | 2,200 lbs [1,000 kg] |

| Material of Construction | 304 stainless steel frame structure, 316 stainless steel product contact surfaces |

| Surface Finish | Product Contact Area: 25 µin [0.64 µm] Ra with ground and polished welds Non-Product Contact Area: 35 µin [0.89 µm] Ra with smooth welds as laid |

| Utility | Air Supply: 90 PSIG [6.2 bar], 8 SCFM [3.1 L/s] clean, compressed air Electric: 120 VAC, 1 Phase, 60 Hz and 480 VAC, 3 Phase, 60 Hz Pneumatic or Electric (Battery) Utility Options Available |

| Controls | touch-screen HMI with separate E-Stop and on/off switch |

| Hazardous Rating |

configurable for use in Hazardous Locations: Class I Divisions 1 and 2, Class II Divisions 1 and 2, ATEX Zone 2 or Zone 22

|