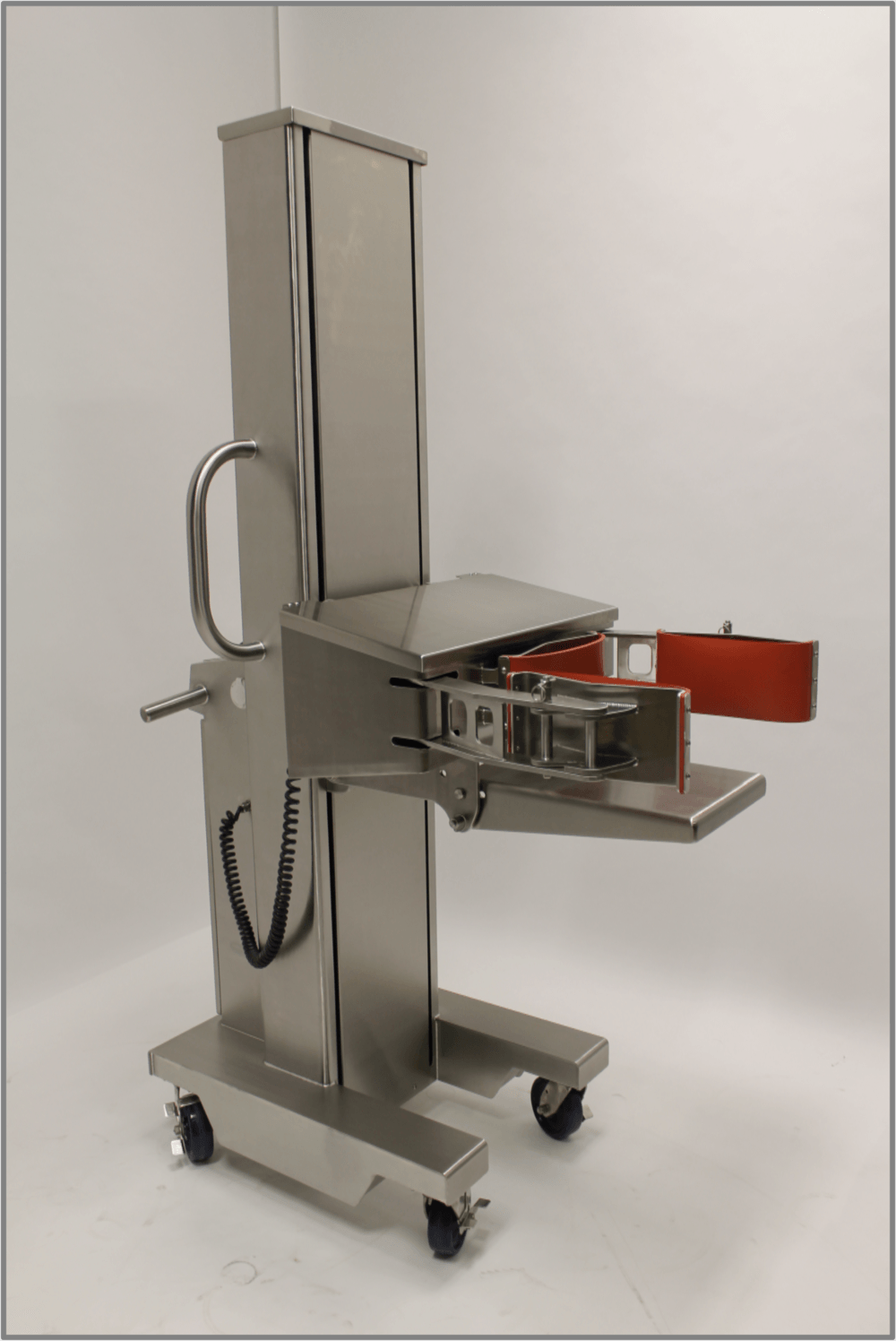

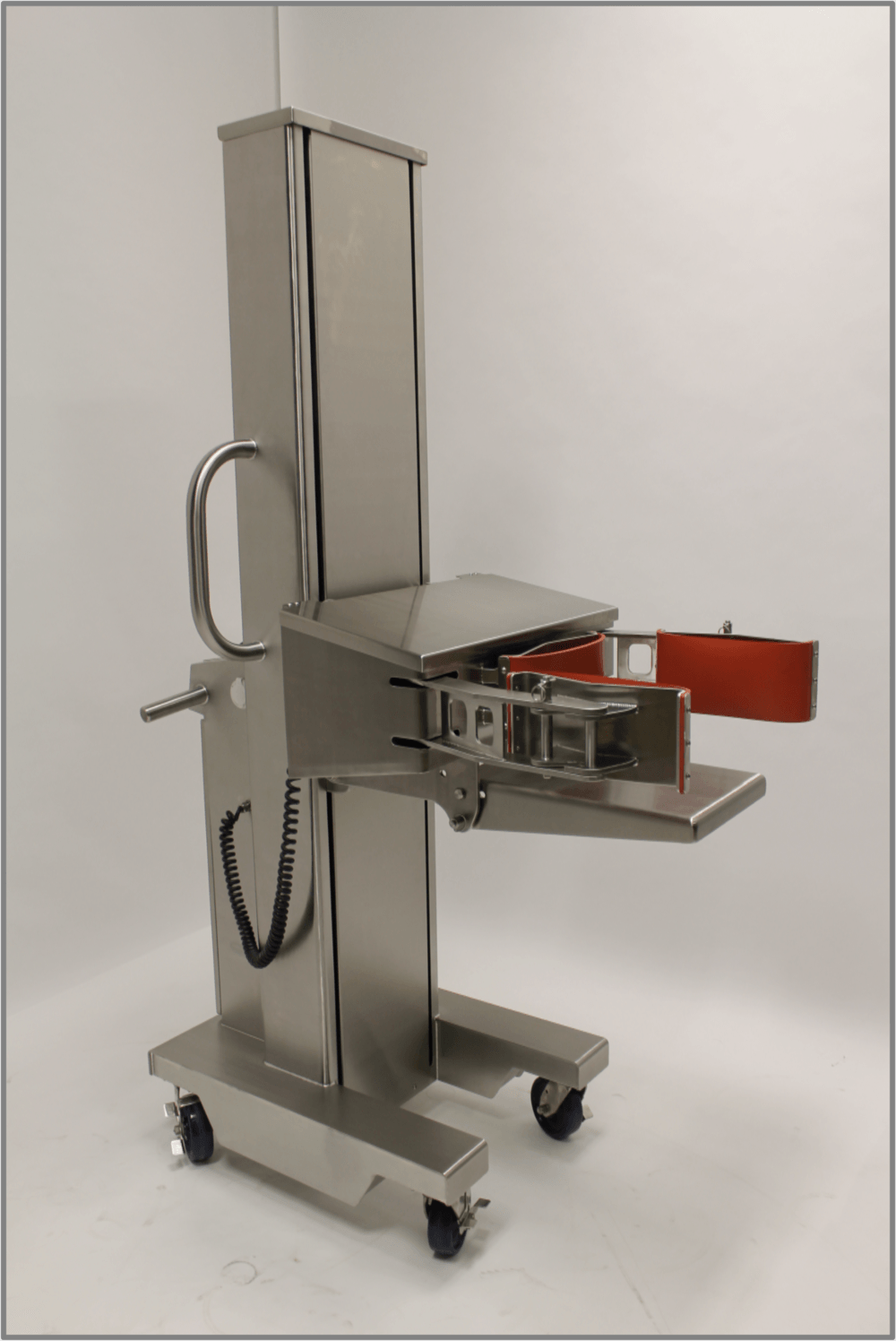

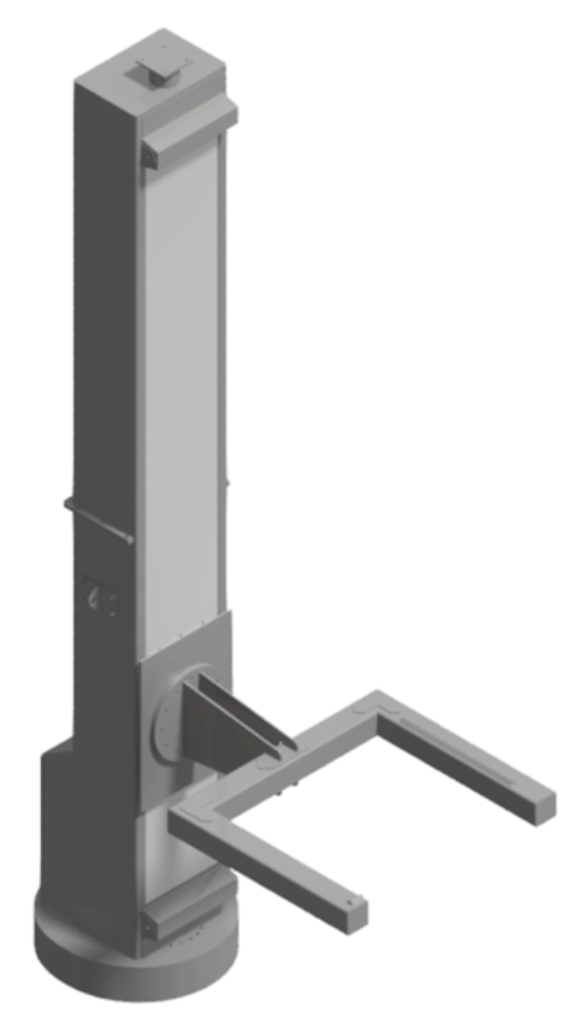

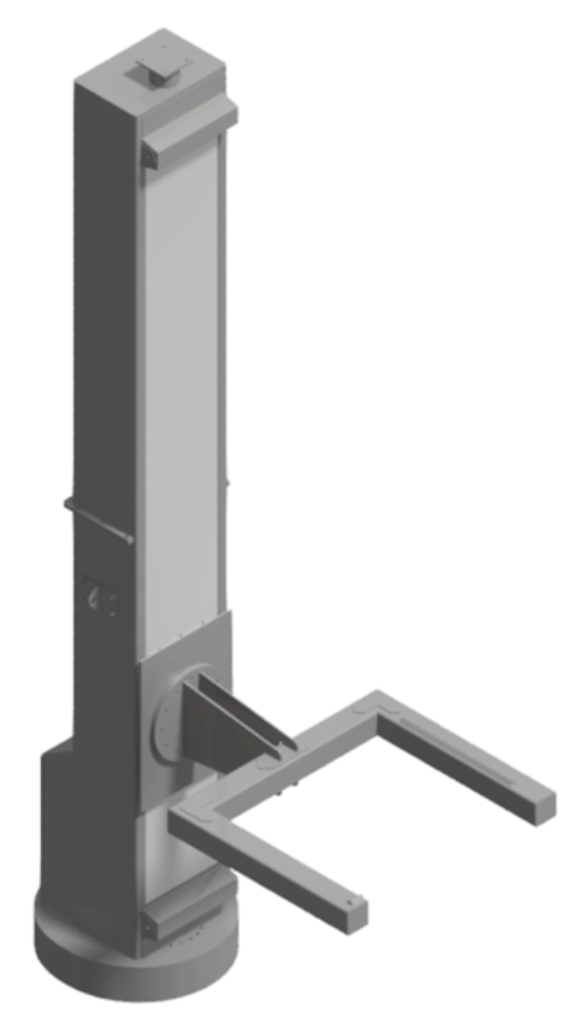

The Rheo Column Lift is designed with a customizable lift carriage so that various attachments can be used. Column Lifts can be mobile or stationary and can be designed as a simple material lift or as a man lift with redundant safety systems.

Column Lift

Features

The Column Lift has several benefits when implemented in the manufacturing process:

- Easy To Clean

- Low Maintenance

- Customizable

Common Specifications [customized per application]

| Load Capacity | 650 lbs [295 kg] |

| Material of Construction | 304 stainless steel |

| Surface Finish | 35 µin [0.89 µm] Ra with smooth welds as laid |

| Utility | Electric: 480 VAC, 3 Phase, 60 Hz Pneumatic and Electric (Battery) Utility Options Available |

| Controls | momentary push button controls on wash-down control pendant |

| Hazardous Rating | configurable for use in Hazardous Locations: Class I Divisions 1 and 2 [ATEX Zones 1 and 2] or Class II Divisions 1 and 2 [ATEX Zones 21 and 22] |

Base Configurations

The Rheo Column Lift can be configured with two different styles to best fit the specific application.

Free Standing

The Free Standing frame is fully mobile, requiring no floor installation.

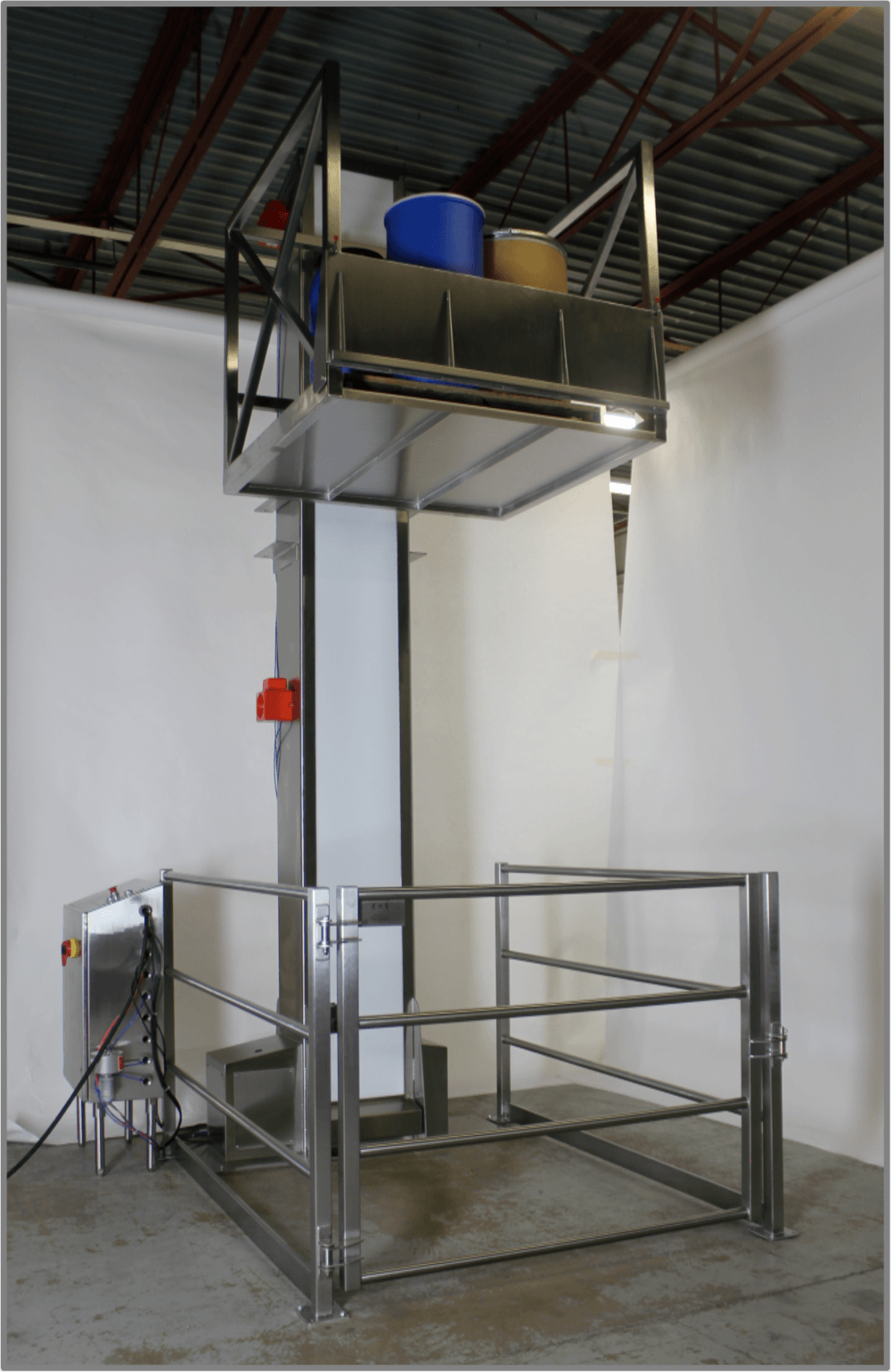

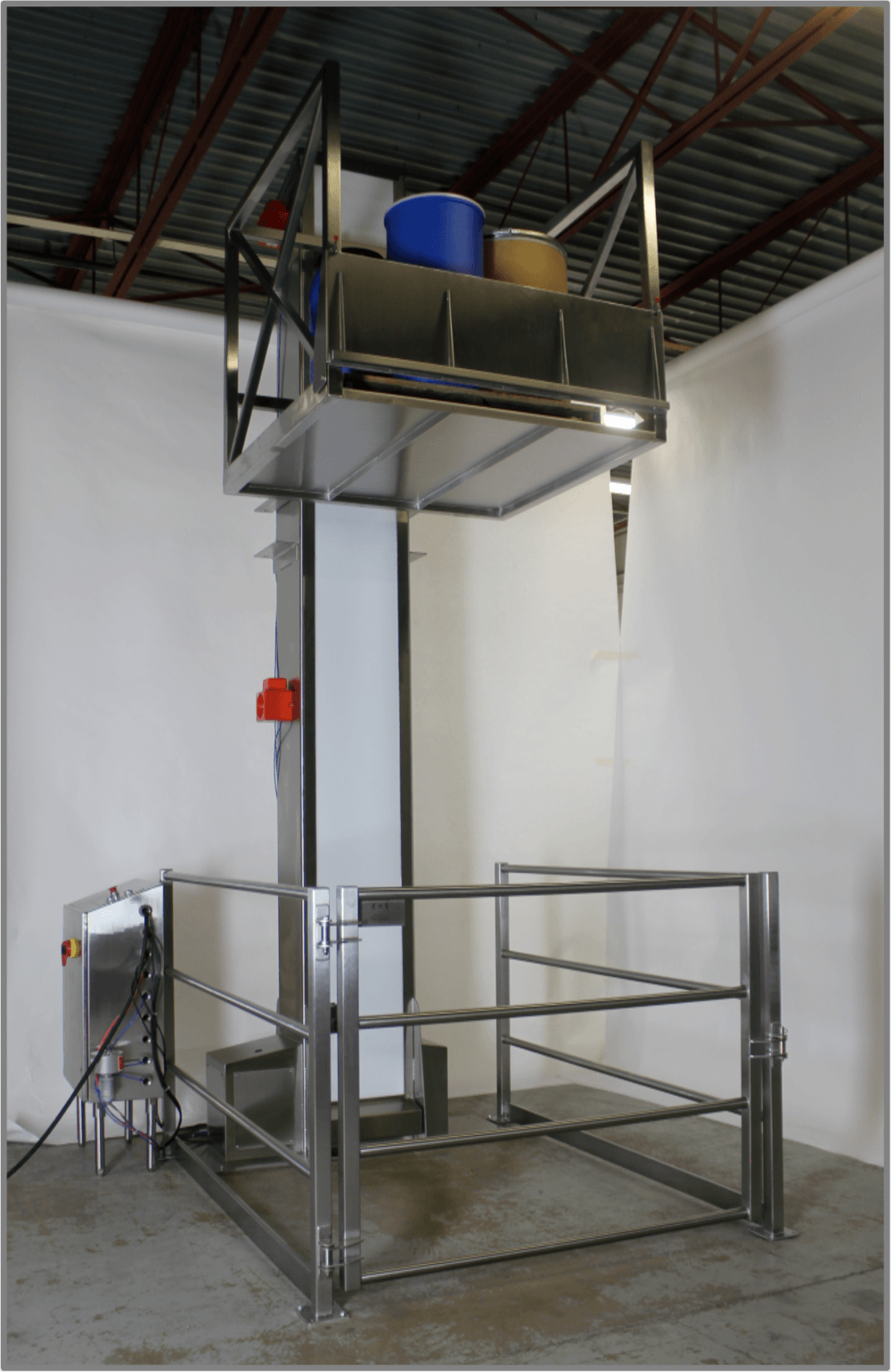

Fixed Mount

The Fixed Mount frame is a bolt down design for a fixed installation. Ceiling support is optional.

Fixed Slewing Column

The Fixed Slewing Column loads in one position and then rotates. Ceiling support is optional.

Customizable

Lifts are configured to match the size, weight, and required elevation of the load to be raised. Material Lifts are designed with multiple safety interlocks to ensure the safe and reliable delivery of materials to required height. Each unit is customized for the various containers that are being lifted.

Common Applications

- Multi-Level Process Staging

- Man Lift

- V-Blending

- Ribbon Blending

- Chemical Reactor Process