MTS – In-Floor Charge Chute Transfer with Rigid Isolator

Choose a configuration below.

Select Your Containment Option

Select Your Process Option

In-Floor Charge Chute Transfer with Rigid Isolator

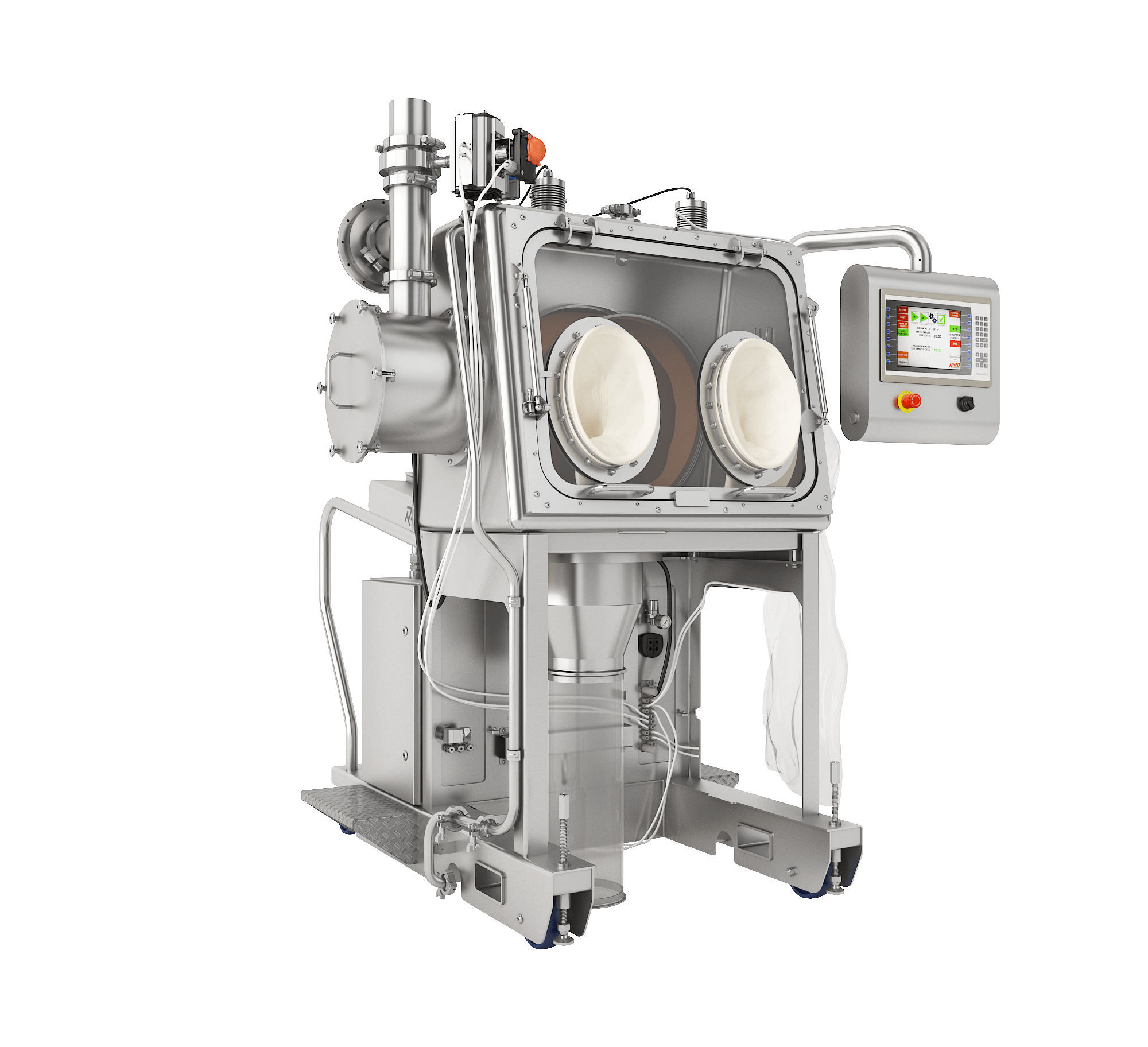

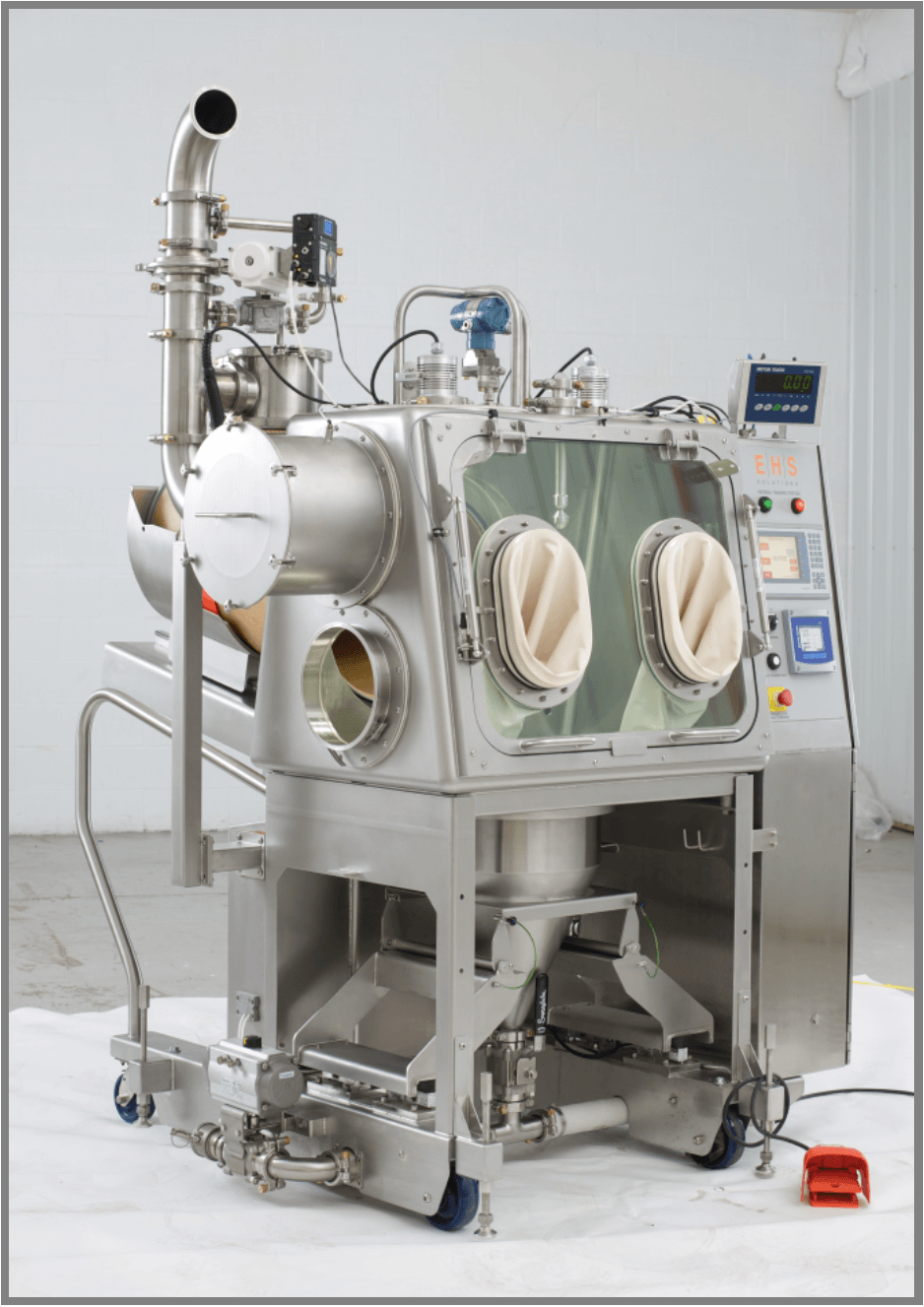

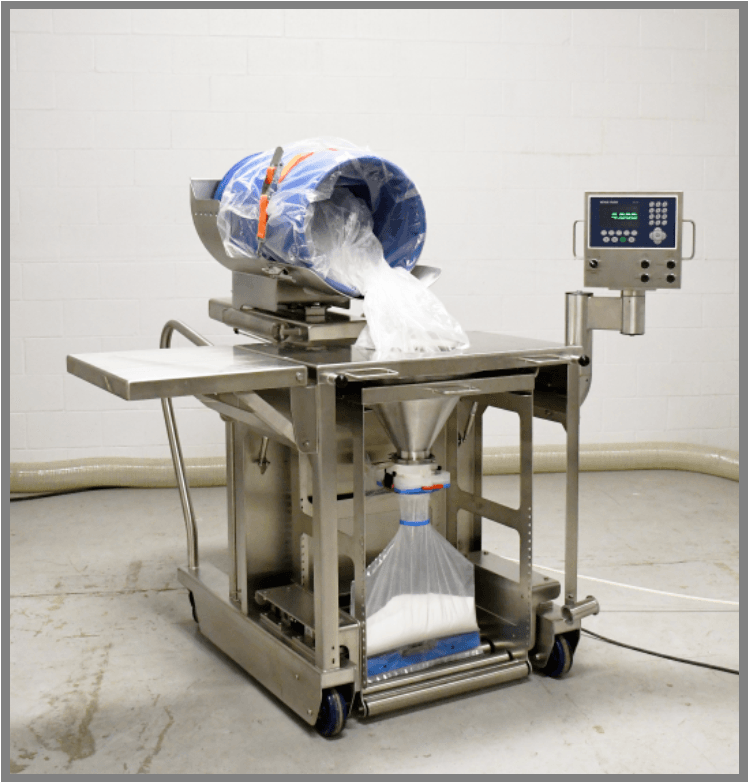

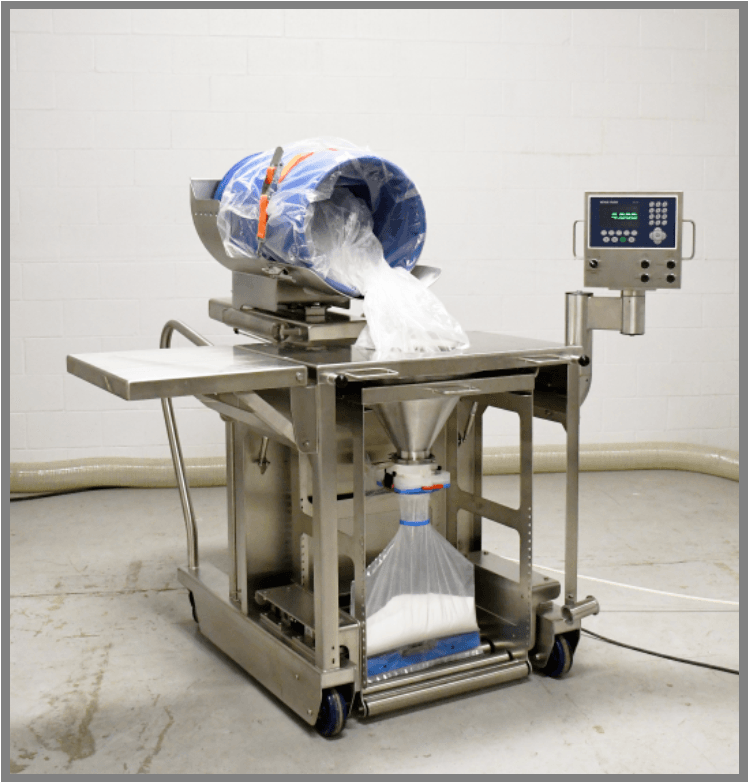

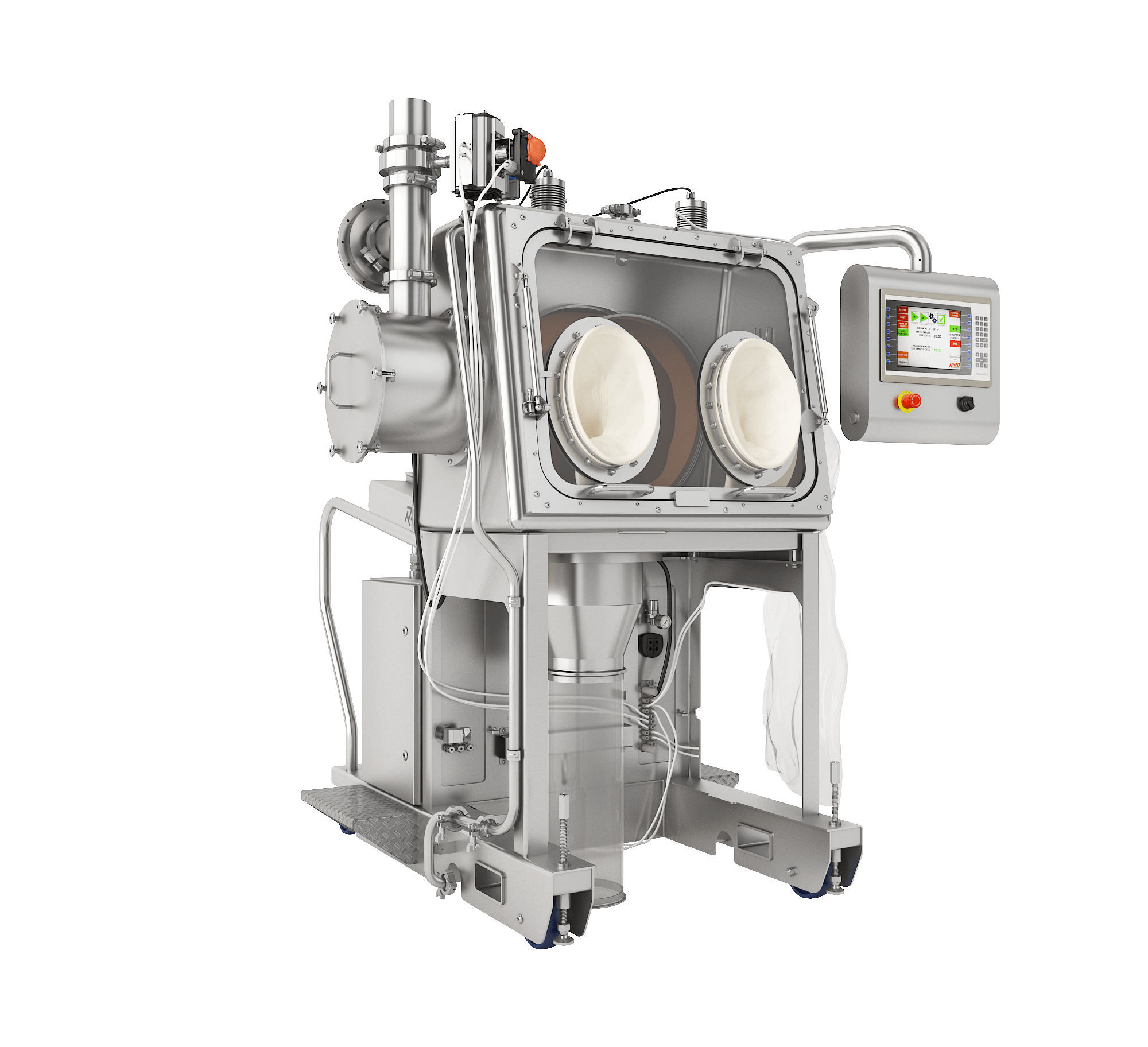

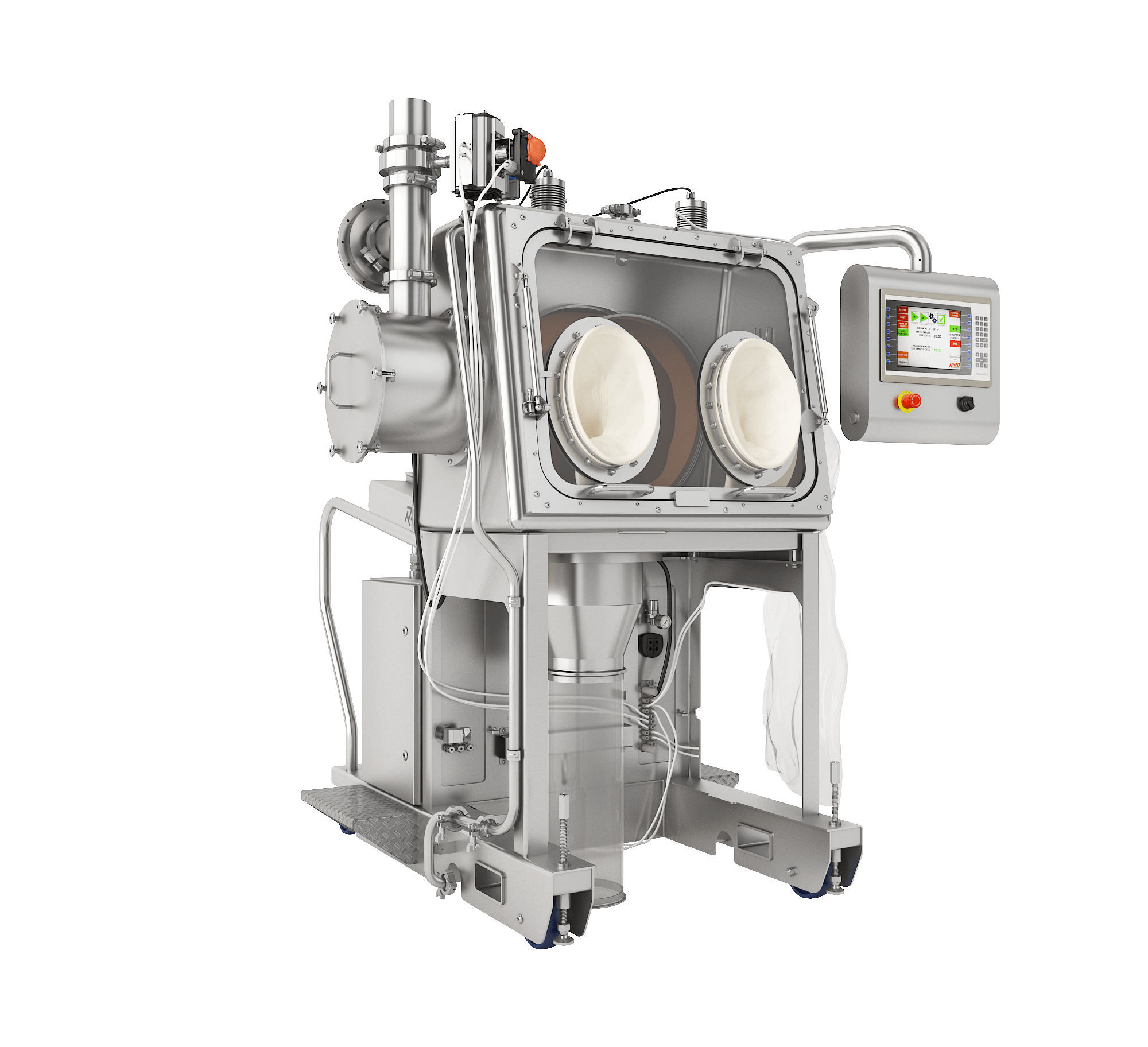

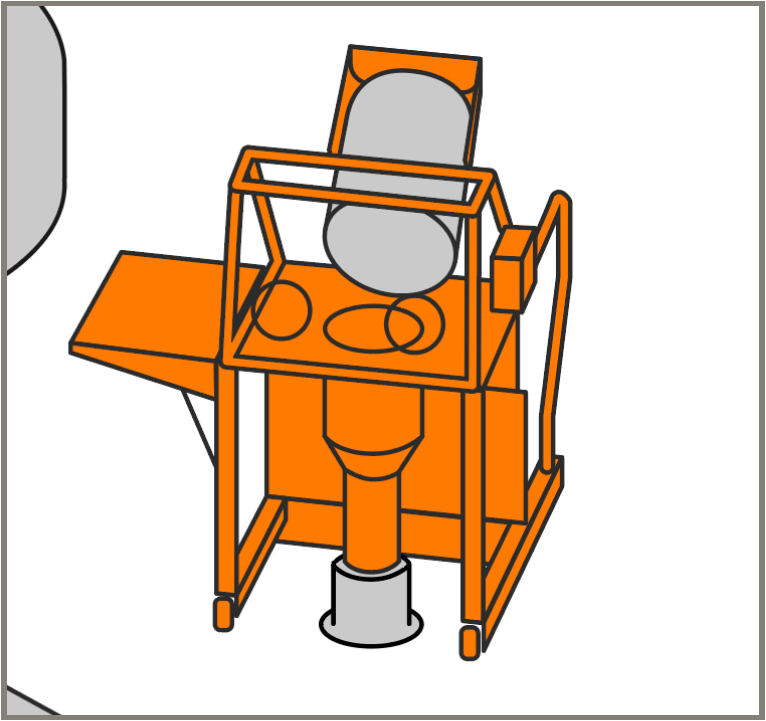

The Rheo Material Transfer Station is a small footprint workstation that improves operator safety and efficiency during the material transfer and weighing process. The operator workstation with the integrated drum tipper provides a compact, GMP, ergonomic means of transferring material.

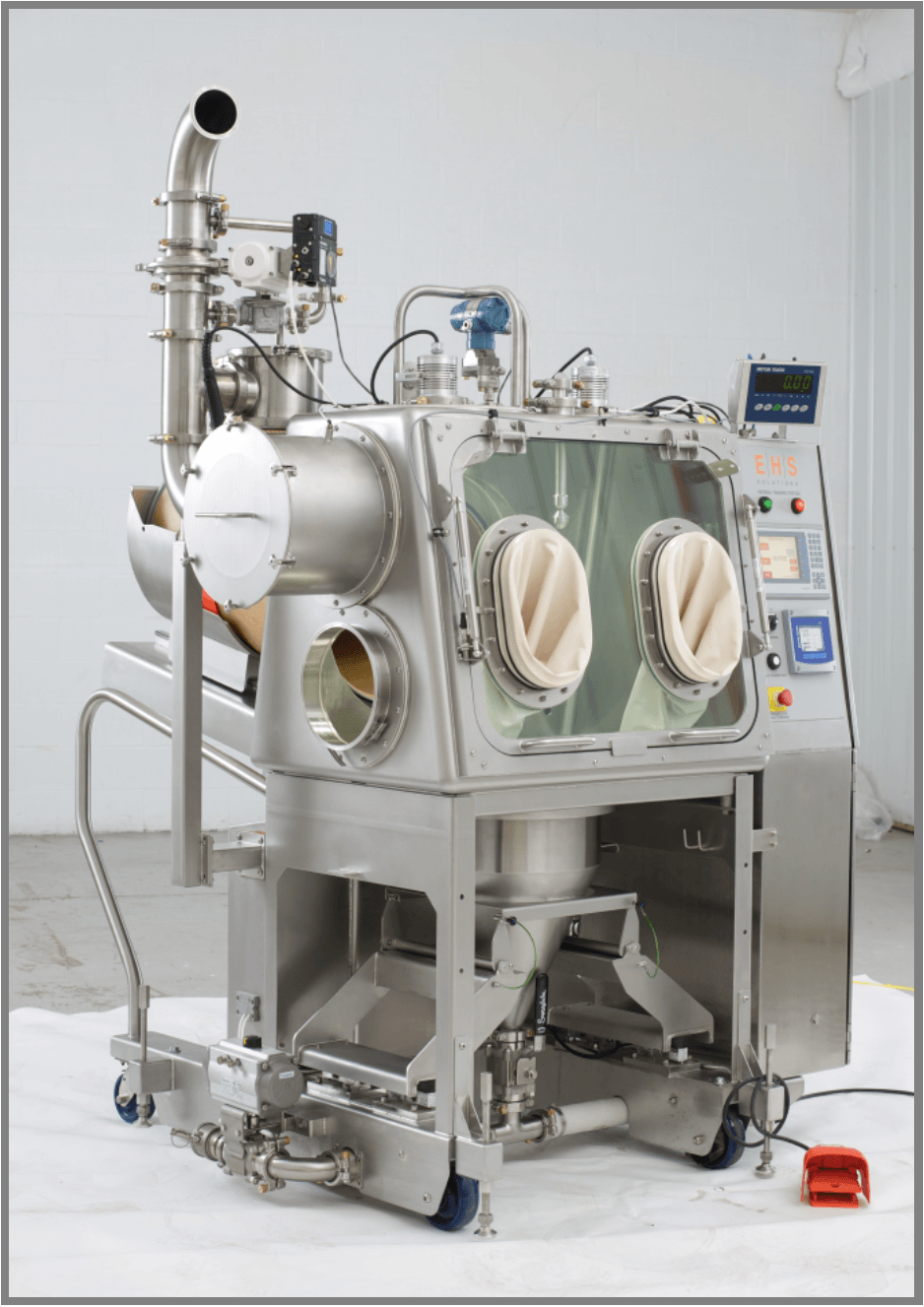

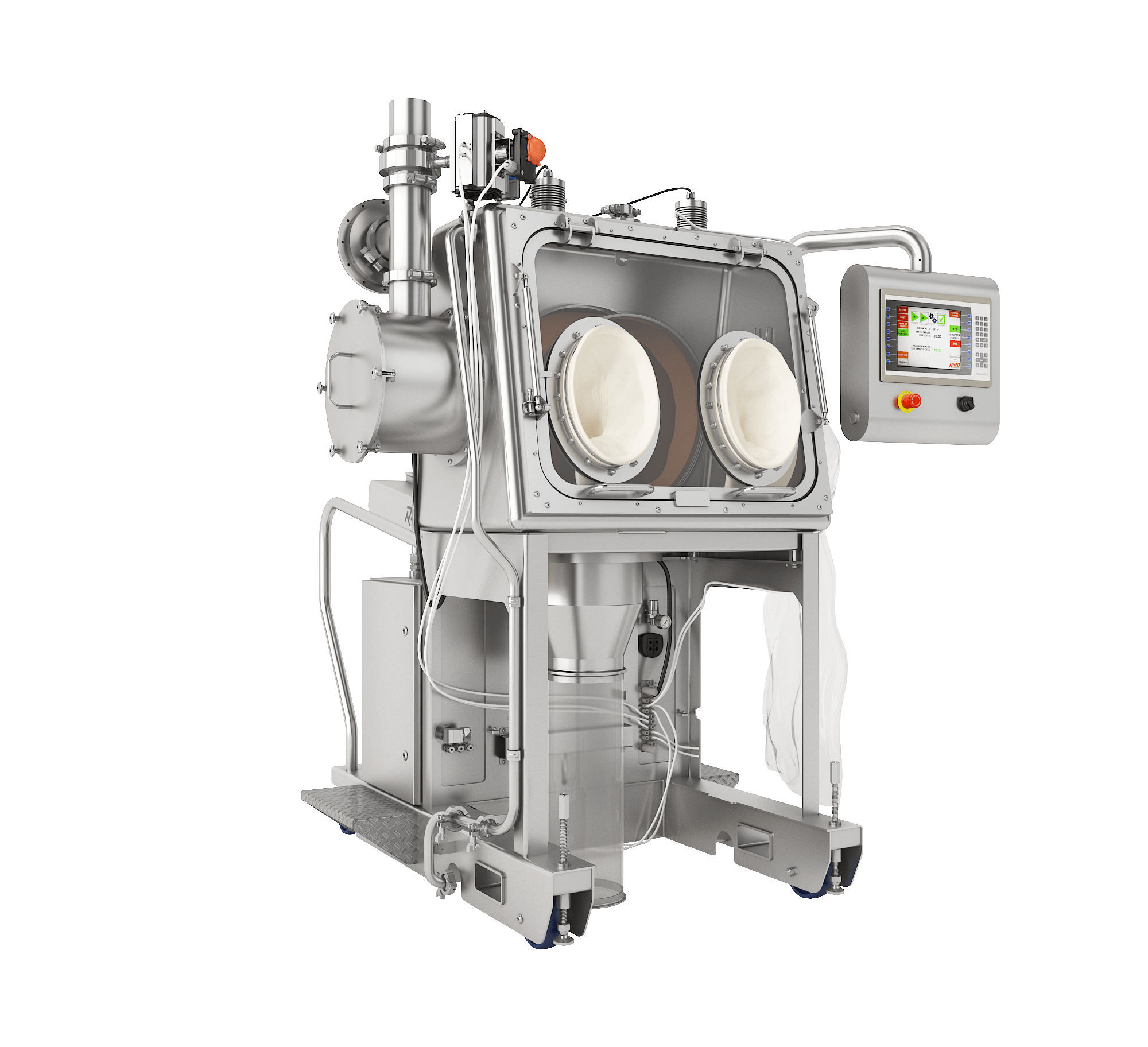

The Material Transfer Station with Rigid Glovebox Containment is designed for highly contained, closed transfers for highly toxic products and APIs. Containment levels of 1-0.01 µg/m3 can be achieved via the rigid glovebox.

Rheo has conducted performance verification tests on the Material Transfer Station. The tests showed excellent results for each of the different configurations tested. Copies of the executive summary, full reports, and supplemental documentation are available upon request.

The In-Floor Charge Chute configuration is used to transfer materials from drums through an in-floor chute for charging vessels on a lower level.

Features

The Material Transfer Station with Rigid Glovebox Containment has several benefits when implemented in the manufacturing process:

|

|

Handles:

designed to help ergonomically position the Material Transfer Station.

Drum Tipper:

integrated Drum Tipper with Powered Drum Slide for easy dispensing.

Casters:

non-marking rigid or swivel casters for GMP compliance.

Operator Controls:

wash down control pendant on articulating arm with momentary push button controls and optional weighing readout.

In-Floor Charge Chute Transfer Module

Rigid Glovebox:

environment can be controlled to the desired specifications, achieves containment levels to 1-0.01 µg/m3.

Front Panel:

safety glass on gas-spring lift assist, sealed via perimeter inflatable seal.

Sprayball:

WIP/CIP system for inside the glovebox.

Glovebox Lights:

LED lighting for improved visibility in the glovebox.

Closed Transfer Systems

The In-Floor Charge Chute Transfer Module connects the Material Transfer Station directly to an in-floor chute. For Rigid Closed Transfer Containment, the top of the transfer module will be connected to the glovebox using an inflatable seal, or a short transfer chute, while the bottom is clamped to the in-floor chute. Using this process to provide containment is designed to keep operator particle exposure to 1-0.01 µg/m3.

Controlled Environment

The rigid glovebox can be controlled by a programmable logic controller to monitor and maintain a safe operating environment within the glovebox. The operating conditions are customized to a specific application and automatically change based on what mode the glovebox is in. A touch-screen HMI is used to control the operating mode and to display the system conditions or give user prompts. Glovebox pressure and oxygen concentrations are the two primary operating conditions that are controlled.

Common Applications

- Reactor Charging

Integrated Weighing

The integrated weighing system provides a compact solution for the weighing and dispensing operation. The weighing module that holds the receiving container is isolated from the workstation to provide excellent weighing accuracy.

The typical integrated weighing system includes the following features:

- 150 kg Weighing Capacity

- Mettler Toledo IND570 or IND560X Readout

- 4x Mettler Toledo Load Cells

- Weigh Accuracy to +/- 50 grams (higher accuracy, low capacity options are available)

- Can be Integrated with Computer, PLC, or Printer

Drum Tipper

The integrated pneumatic Drum Tipper can be used to lift a wide variety of incoming containers and slide it towards the operator for easy dispensing into the receiving container. Pneumatic controls provide safe, controlled operation of the Material Transfer Station.

- 150 kg Drum Capacity

- Pneumatic Drive System (90 psig, 8 scfm Clean, Compressed Air)

- Material of Construction: 304 Stainless Steel Frame Structure, 316 Stainless Steel Drum Cradle and Product Contact Surfaces

Operator Centric Design

By designing around an analysis of operator movements during the drum charging process, an unmatched level of safety, operating simplicity, and functionality is achieved. A drum can be raised, lowered, and tipped into the proper position by using a single hand or foot control. This approach to drum handling allows the operator to easily control the product flow during the entire charging process.

Cleanability

All exposed surfaces on the Material Transfer Station can be fully washed-down for cleaning. Some configurations of the Material Transfer Station include WIP spray-ball systems to wash the product contact surfaces.

Testing Center

Powder handling can be a challenging process and there are many factors that lead to the optimal solution. We can handle the risk for you! Our Testing Center is equipped to test your materials, allowing us to design the best solution for your specific needs. We don’t just sell a product – we sell a solution.

We can utilize the Testing Center for process testing, powder flow testing, transfer rate testing, concentration testing, and containment performance verification.

Reach out to your Regional Sales Manager to discuss the testing of your next bulk powder handling project.