[Patent Pending]

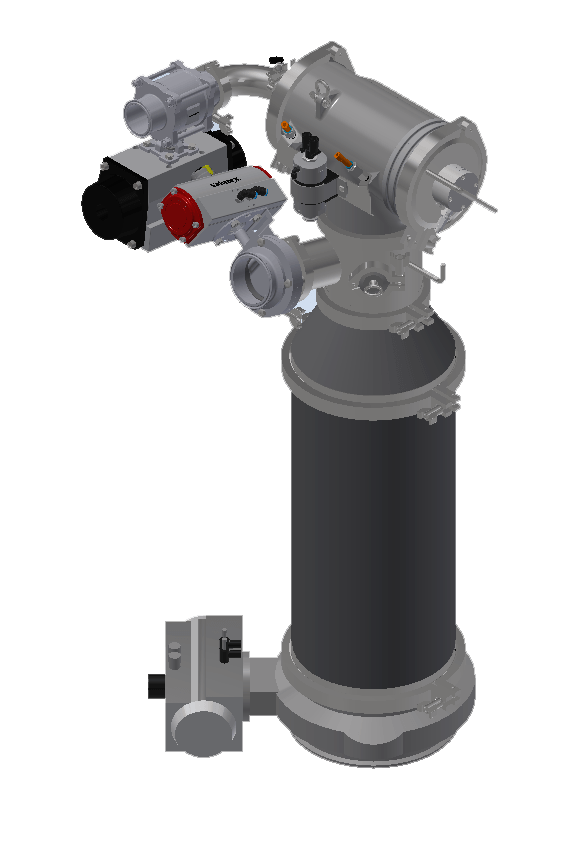

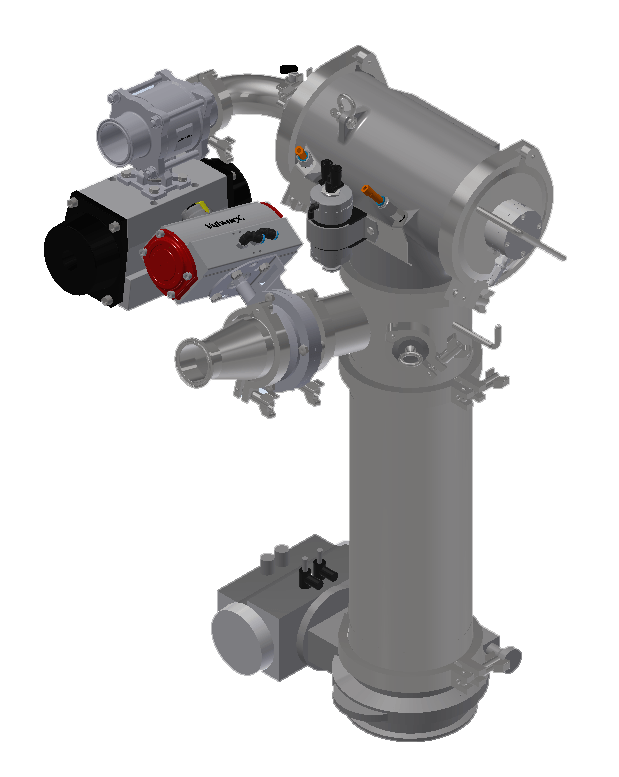

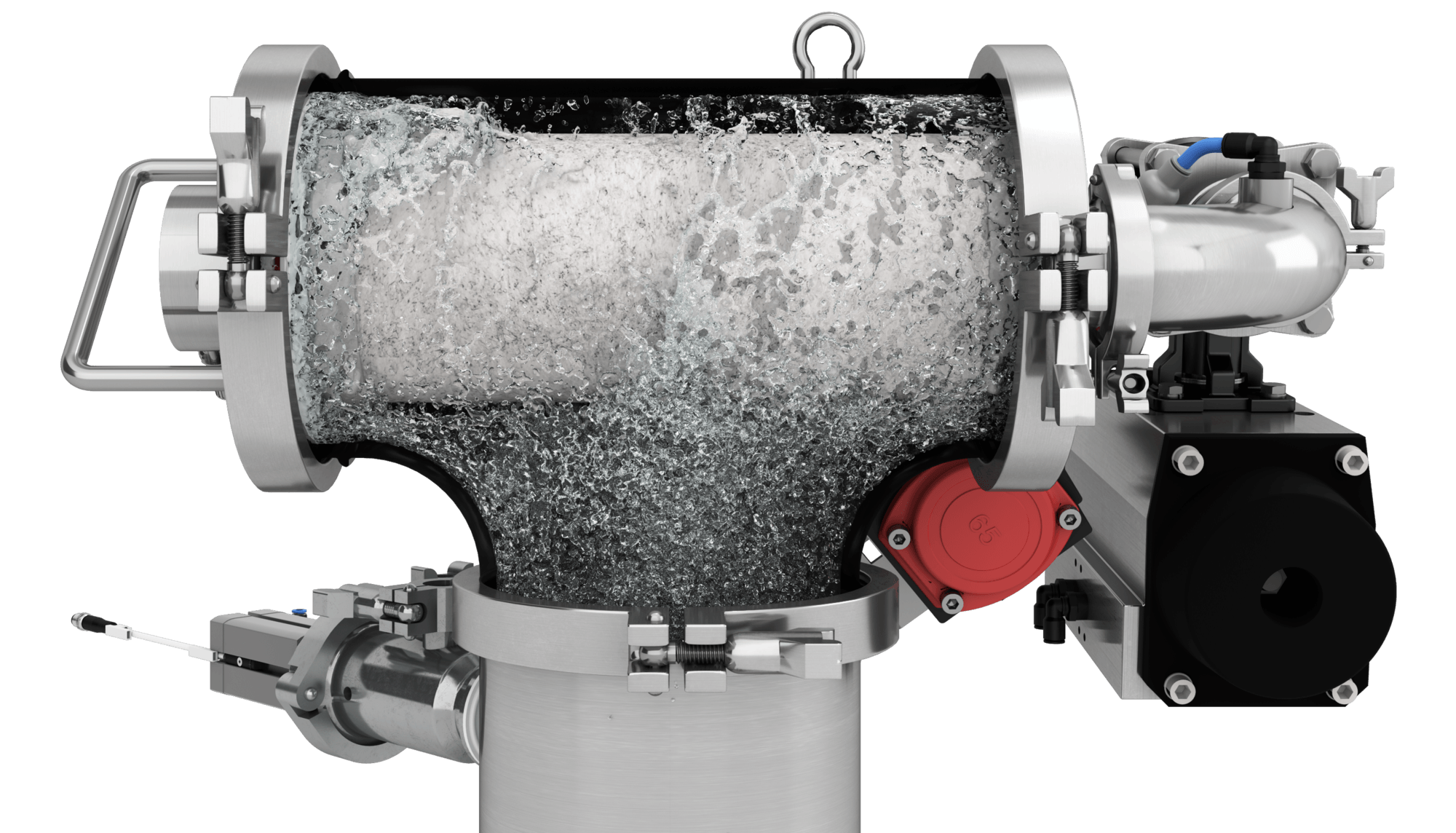

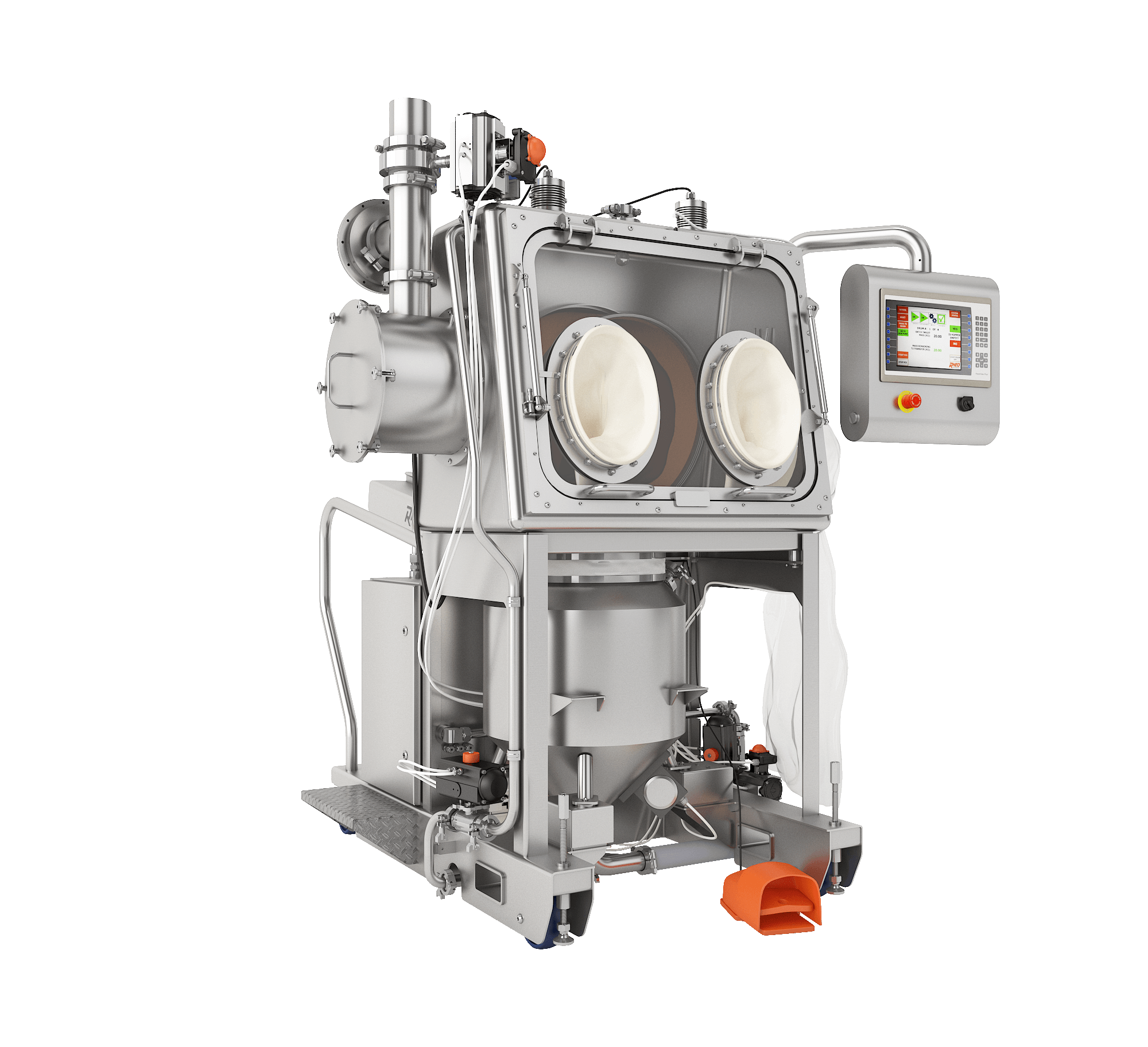

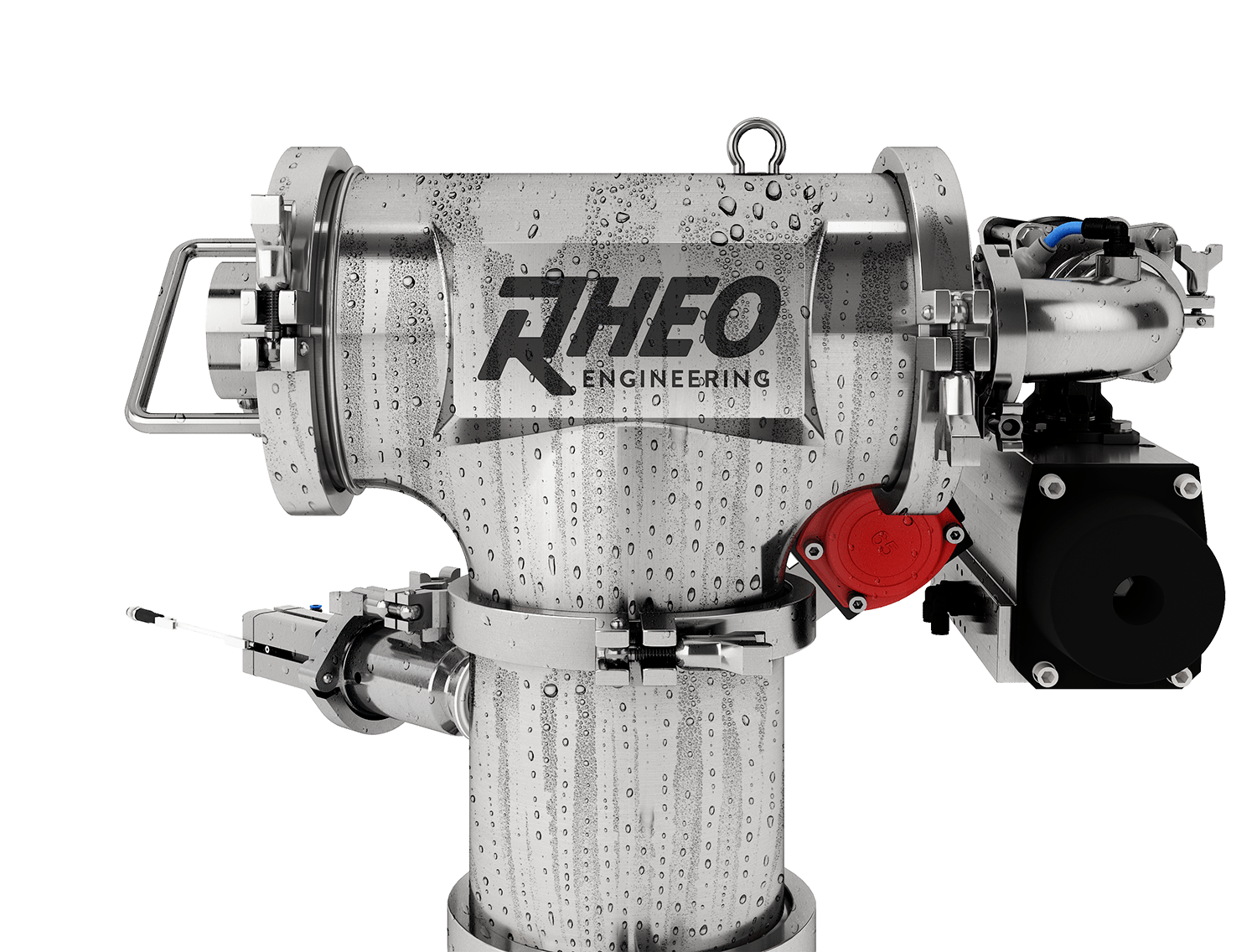

The Rheo Vacuum Conveyance System [Patent Pending] provides a safe, efficient, and contained means for transferring material using a vacuum source instead of relying on gravity. The Vacuum Conveyance System is ideal for transferring highly toxic or potentially explosive powders that are present in the pharmaceutical, food, and chemical industries.

Safety: Creates a closed transfer system that can achieve containment levels of less than 1 μg/m3. For potentially explosive products, nitrogen can be used to ensure the product is flooded with nitrogen before being discharged to the receiving vessel.

Efficiency: Continuously transfer material without operator involvement, which can eliminate one entire step of the manual material transfer process. Control systems allow for optimization of flow rates for various materials and conditions.

Reliability: Automated controls ensure a repeatable process.